About the 9905-997

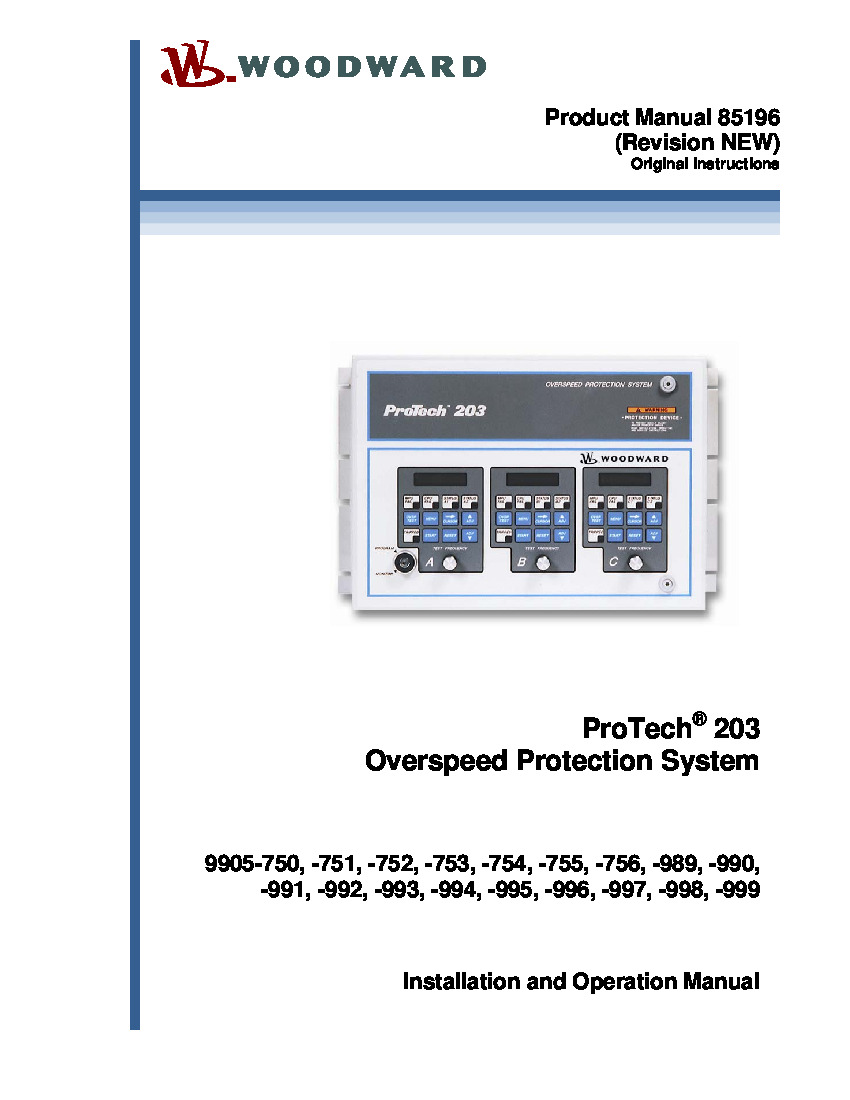

This overspeed protection system has three speed-sensing units contained in a locked, IP 65 (similar to NEMA 4) certified enclosure with an operator interface for each unit on the front panel. There are three 220 Vac power supplies for this system, one for each unit.

Trip Speed Set Point, Magnetic Pickup (MPU) Failed Set Point, Trip on MPU Failure, MPU Gear Teeth, and MPU Failed Timeout are the tunable parameters set using the LCD and keypad of each operator interface. These parameters can be viewed on the LCD during operation along with Present Speed, Peak Speed, and Trip Cause. Present Speed for each speed-sensing unit is the default first parameter shown on that unit’s LCD.

Units A, B, and C are identical, and all follow the same process for monitoring prime mover speed and performing speed calculations. Speed is sampled every 5 ms using MPUs and after speed calculations are performed, a hardware two-out-of-three vote determines whether overspeed conditions are met.

Any individual unit will trip when its present speed exceeds its Trip Set Point, but only an overspeed detection by at least two of the units will cause a trip relay to take the prime mover offline. This system design also permits hot replacement and testing of individual units while the prime mover is online.

When a unit trips, it remains tripped until it is either reset or the power is cycled. Units must all be reset before the turbine is started, but ProTech model 9905-997 has a remote reset feature to keep this step simple.