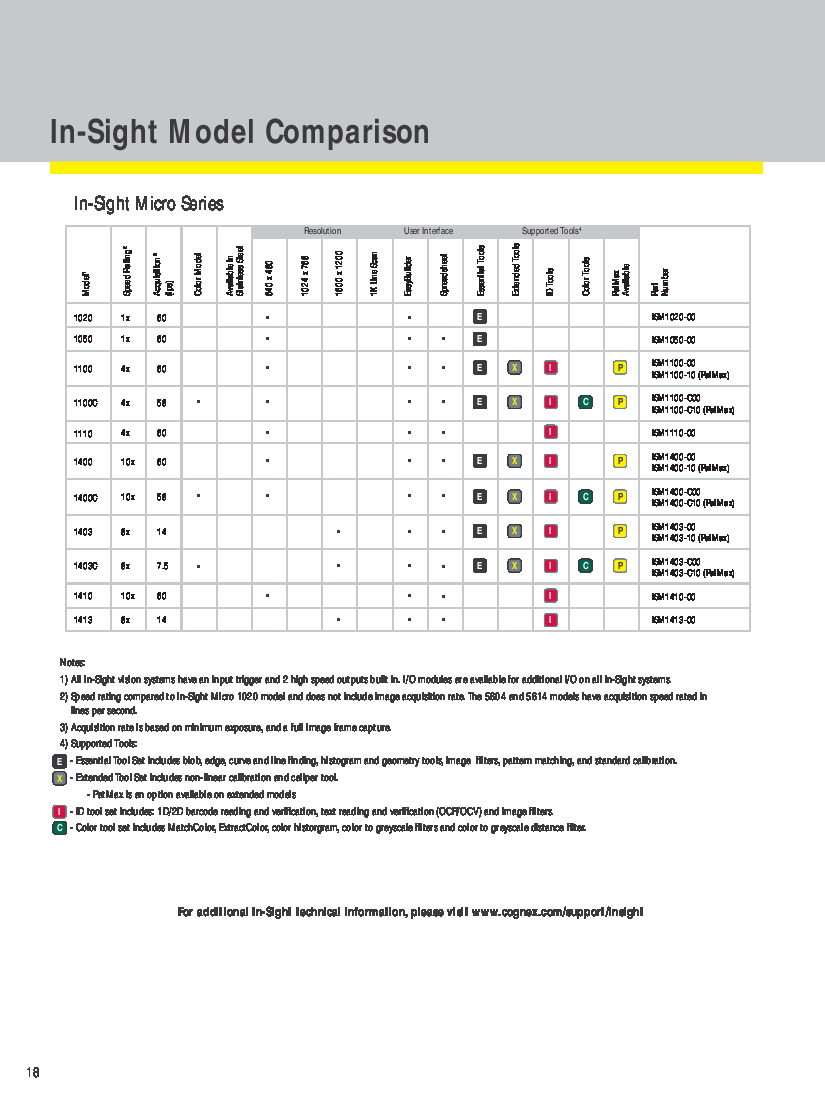

About the ISM1100-C10

The ISM1100-C10 Vision System was designed with three main applications in mind; this unit was designed to guide, inspect, and identify several things, one of which is to inspect factory merchandise through the entire manufacturing process. Inspection of the merchandise throughout the manufacturing process helps reduce the possibility of rework of products as well as reducing scrap in case significant defects have occurred throughout the production process.

Not only will this model be used in the aforementioned applications but the supported features and toolsets help enhance the model. For example, the color setting of the ISM1100-C10 vision system helps identify and inspect parts simply based on color. The principal applications of the enhanced color system help the model identify LEDs by color which helps with the proper assembly; the color system will also study the parts and their color to make sure that the quality of each product is remaining consistent throughout the manufacturing process. All of the features and applications that have been referenced in this description can be found in the Cognex In-Sight Vision Product Guide, please note that the features mentioned are just some of the features and more can be found in the Product Guide.

The ISM1100-C10 model has flexible display options which also amplify this unit. The display options on this model make the system ideal for controlling and monitoring not only the standard vision systems but industrial ID readers typically found on the factory floor and will allow the user to control the specifics of the application.