About the ISM1400-C00

When the ISM1400-C00 model is being operated it is typically operated it will be used in a setting in which parts need to be identified. This vision system can identify parts by alphanumeric characters, color, barcode, or even shape. This model is one of the most accurate and reliable systems to identify parts on some of the most accelerated production lines in the industry. A system such as this can provide unmatched one-dimensional and two-dimensional code reading performances as well as a wide field of breakdown to the appearance of the code with the industry’s most trustworthy read rates.

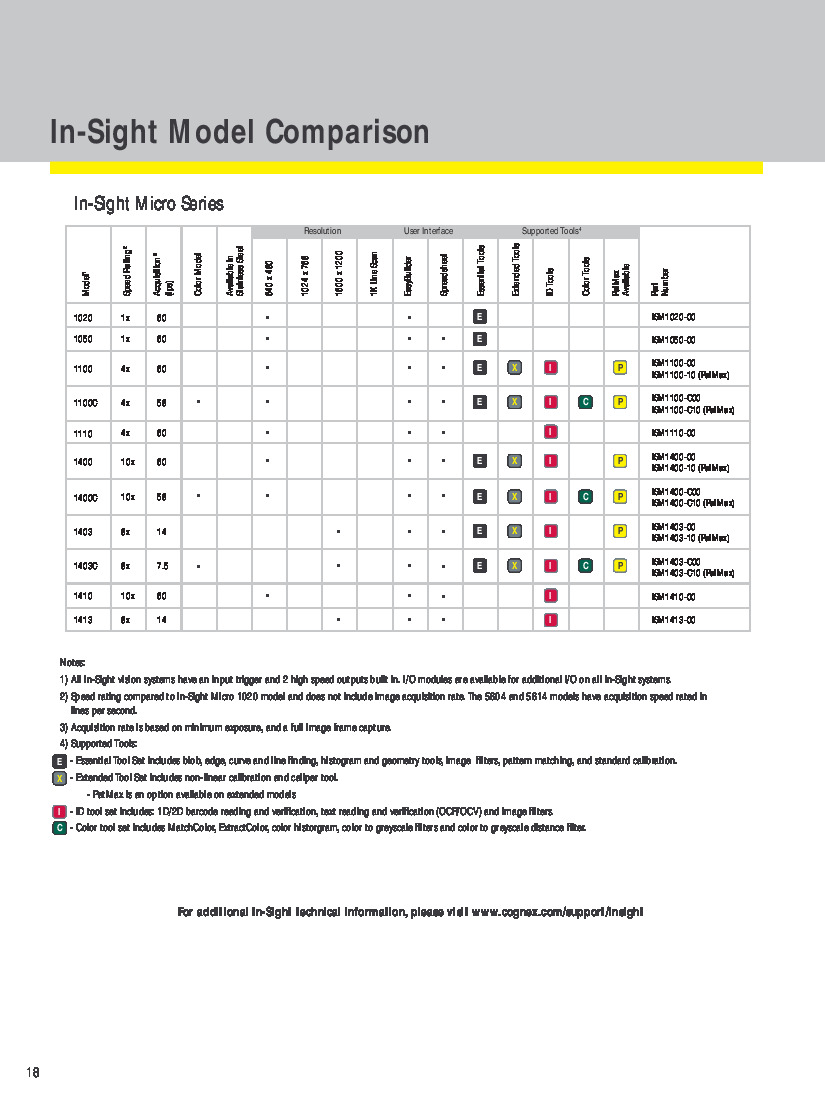

The primary specifications that make this model one of the best to use are the variety of different support tools. The support tools associated with this model are the essential, extended, color, and ID tools; there is also a potential for a PatMax tool. When using the extended toolset there are two main tools used which are a caliper and a non-linear calibration tool. The main usage of the non-linear calibration tool is to improve precision by correcting the lens and perspective distortion. All of the other features regarding the support tools can be found in the Cognex In-Sight Micro Vision Data Sheet which is attached to this page under the manuals tab.

There are three cables that are used with the ISM1400-C00 model, which are a breakout, I/O module, and Ethernet cables. There are multiple different lengths for each cable, for the breakout cable there are only five lengths, which are 0.6, 2, 5, 10, and 15 meters. Each of these cable lengths has a different part number association.