About the DS200CVMAG3

As identified in this DS200CVMAG3 product offering's original General Electric instructional manual materials, this DS200CVMAG3 printed circuit board product offering was originally developed for GE's Mark V Turbine Control System Series. As you might be able to tell by its full extended series name, the Mark V Series that this DS200CVMAG3 PCB product offering belongs to has specific applications in the management and control systems of popular and compatible wind, steam, and gas turbine automated drive assemblies, and is considered a legacy product series, given its eventual obsolescence-necessitated manufacturing discontinuation that took place in the many years since its original release. This DS200CVMAG3 printed circuit board product offering's greater Mark V Series, while a legacy General Electric Mark product series, is definable as one of the final General Electric Mark product series to make use of their patented Speedtronic control system technology first seen with the release of the Mark I Series in the late 1960s. This DS200CVMAG3 PCB is definable as a Generator Control Turbine Board, and is additionally definable as the original, base-revised product of this specific Mark V Series functionality, given its DS200CVMAG3 functional product number's concerted lack of any revision-indicating trailing digits.

Hardware Tips and Specifications

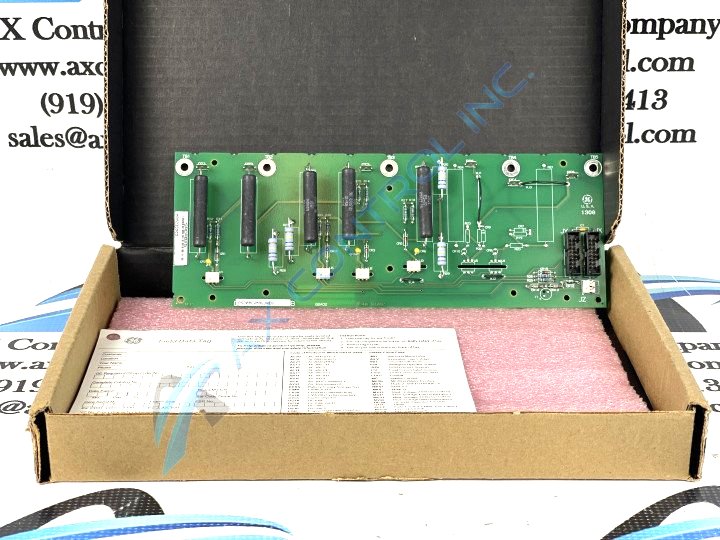

The GE Generator Control Turbine Board DS200CVMAG3 contains two 16-pin connectors and one 2-pin connector. The board also is populated with 6 test points. The installation of the board requires the installer to potentially be exposed to high-voltage conditions so only qualified individuals should perform the procedure. The installer must know the written procedure for the installation of the board as well as other important information. A knowledge of the drive and the high-voltage cabling used to power the drive is necessary and also knowledge about the emergency cut off devices installed near the drive is important also. As this DS200CVMAG3 printed circuit board product offering belongs to a now-obsolete General Electric Mark product series as outlined above, this DS200CVMAG3 PCB is not well-detailed in any internet-available General Electric instructional documentation. With that being true, the DS200CVMAG3 functional product number itself can be considered a primary source of DS200CVMAG3 Board hardware component and component specification information, as the previously-included information is truly reminiscent of a DS200CVMAG3 Board visual inspection. The DS200CVMAG3 functional product number codes for various DS200CVMAG3 Board hardware specifications in a series of functional naming chunks. For example, the DS200CVMAG3 functional product number begins with the dual-functional DS200 series tag delegating this DS200CVMAG3 PCB's normal Mark V Series assembly as well as its domestic original manufacture location. Some of the other information revealed by this DS200CVMAG3 product's DS200CVMAG3 product number includes its:

- CVMA functional product abbreviation

- Group three Mark V Series product grouping

- Normal PCB coating style

- Absence of any functional or artwork revision

In case an emergency arises, it is important to know the location of the shut-off device and how to activate it. Before starting, the installer must make sure the emergency-shutoff is operational. A knowledgeable installer will work with an assistant or partner on site while the replacement procedure is in progress. The assistant is there to help the installer and be able to turn off the power in an emergency. Another important initial step is to look for water or moisture on the floor surrounding the drive. You must make sure the drive is dry and free of water to prevent electric shock as well as the risk of slippage. Make sure the area has only three prong electric cords to reduce the risk of electric shock. Remove all cords that have only two wires and clear away any devices connected to them. Inform individuals in the surrounding area of the replacement work to reduce the inconvenience to their work schedules.