About the DS200DCFBG1BJB

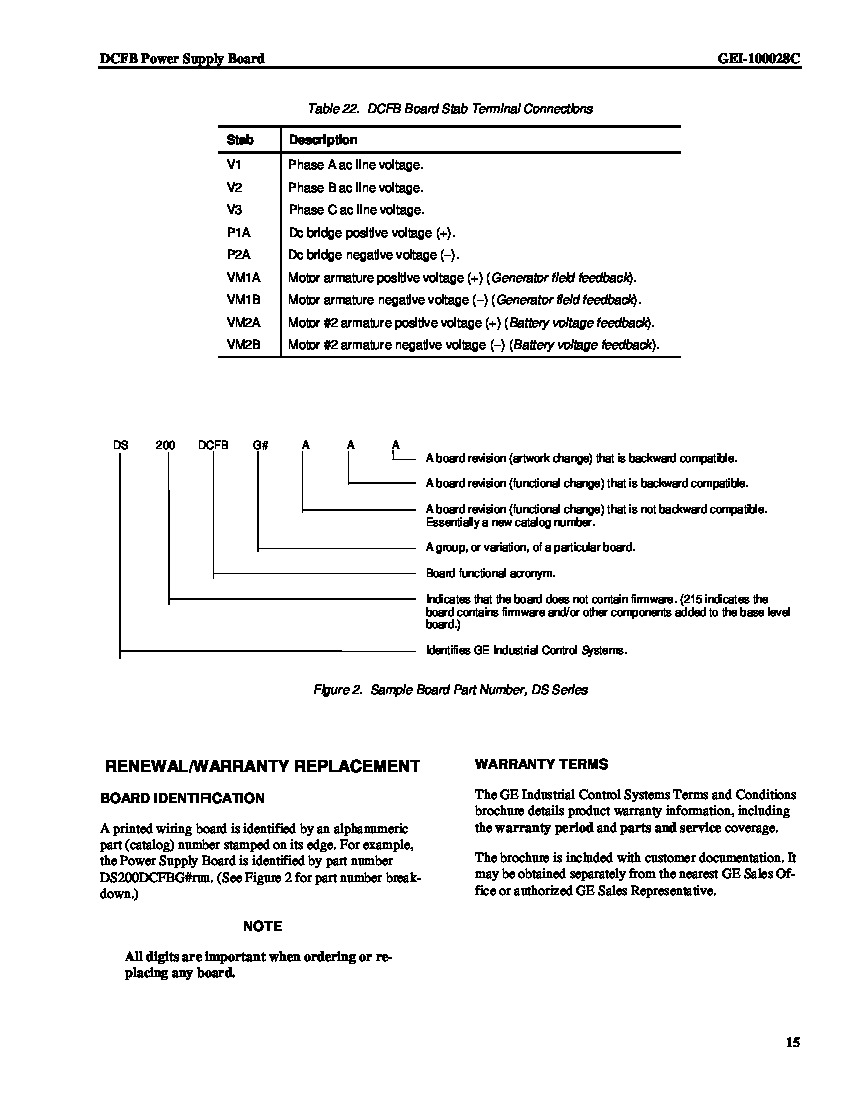

The DS200DCFBG1BJB is a board component manufactured by General Electric as part of the Mark V Speedtronic system. The DS200DCFBG1BJB is used to supply control level power to drives and to the enclosure fan. The DS200DCFBG1BJB is used within EX2000 applications, as well as DC2000, FC2000, GF2000, ME2000, CB2000, and AC2000 IGBT drive applications. The Mark V Series that this DS200DCFBG1BJB product offering belongs to has specific applications in the control and management systems of steam, wind, and gas turbine automated drive assemblies, and additionally exists as one of the final General Electric product series to make use of their patented Speedtronic control system technology. This DS200DCFBG1BJB printed circuit board's greater Mark V Turbine Control System Series is also considered to exists as a General Electric legacy series; given its eventual discontinuation by the original manufacturer in the years following its initial release. This DS200DCFBG1BJB printed circuit board or PCB for short is truly better-definable by its official functional product description as a Power Supply Board, although the original Power Supply Board manufactured for use in the Mark V Series is the DS200DCFBG1 Power Supply Board missing this DS200DCFBG1BJB product's three-fold revision history.

Hardware Tips and Specifications

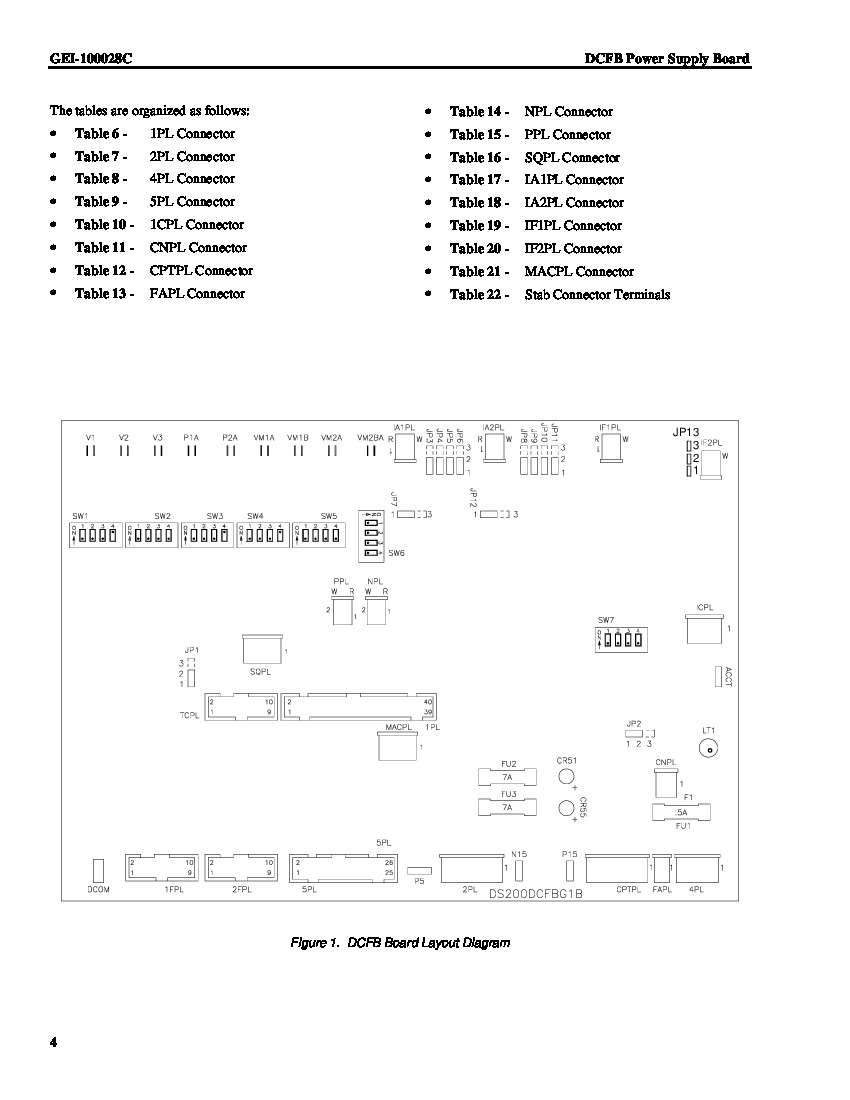

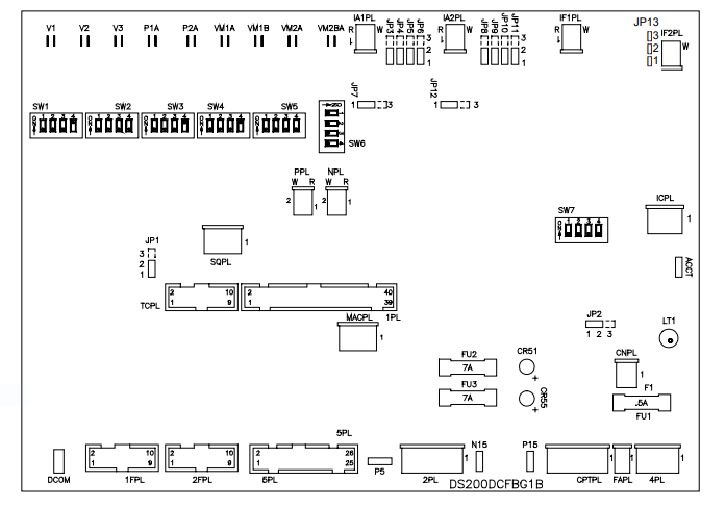

The DS200DCFBG1BJB is a large rectangular circuit board that has a large number of components mounted to its surface. These include seven 4-position DIP switch devices and twelve configurable jumpers. Six of the DIP switches are located together on one side of the board. These are used to scale or change a number of different inputs. For example, switch number 4 (SW4) is used for scaling the voltage applied to the VCO output bridge circuit. The board also has a single neon lamp that is used to indicate a blown fuse in the 115 VAC line and two LED indicators that are used to indicate blown fuses in the +24 VDC line and the -24 VDC line. Several specific integrated circuits of note are available on the base circuit board of this DS200DCFBG1BJB product offering. These integrated circuits, like many of the individual hardware components made available to this DS200DCFBG1BJB product's assembly, are accompanied by their own set of factory-printed nomenclatures, with each circuit providing aid to specific DS200DCFBG1BJB board and greater Mark V Series automated drive assembly functions. The integrated circuits in the assembly of this DS200DCFBG1BJB Power Supply Board include:

- Voltage and Current Feedback VCO Circuits

- A Motor Voltage Attenuation Circuit

- AC Line Maginude and Zero Crossing Circuits

- Contactor Drive Circuits

- Field/Armature SCR Firing Circuits

As mentioned above, each one of the previously-named circuits in the assembly of this DS200DCFBG1BJB printed circuit board has been named through an application of their specific functionality to the greater DS200DCFBG1BJB board and Mark V Series automated drive assembly. This DS200DCFBG1BJB product's various circuits tend to possess crucial applications to the SDCC and LDCC boards within the Mark V Series. These two General Electric printed circuit boards are also available today from our stock of new and reconditioned circuit board products. Other DS200DCFBG1BJB board components include test points, I/O connectors (1PL-1 through 1PL-40,2PL-1 through 2PL-9, 4PL-1 through 4PL-5, and 5PL-1 through 5PL-26), along with fuses, resistor networks and resistors, capacitors, transistors, heat sinks, transformers, and relays. Test points on this board are used to check voltage signals. Fuses are for protection. More detailed information regarding board components and their uses can be found through publications provided by General Electric, like user guides and manuals; attached above in our manuals tab for your convenience. Before making any final purchase decision on this DS200DCFBG1BJB product offering, it is crucial to realize that this DS200DCFBG1BJB board's originally-introduced performance specifications and dimensions have no doubt been altered through its inclusion of a full, three-fold product revision history.