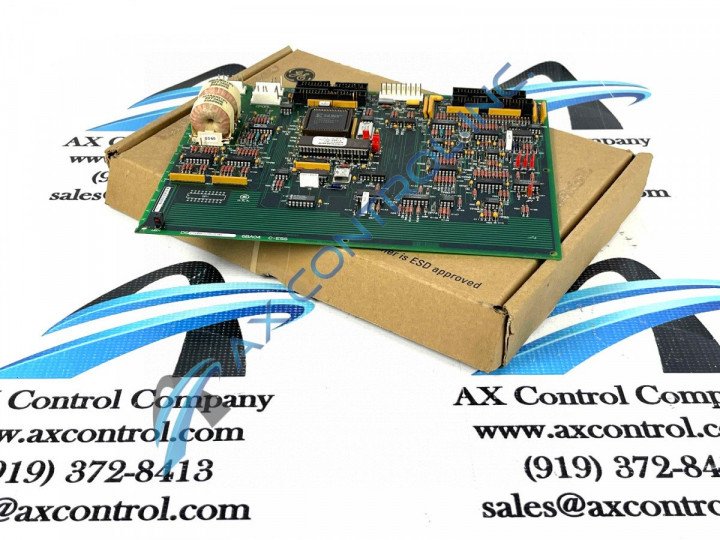

About the DS200GSIAG1CBA

This DS200GSIAG1CBA Common Bus Regenerative Board was originally manufactured for the Mark V Series of turbine control systems, and possesses a normal Mark V Series assembly version. While this DS200GSIAG1CBA printed circuit board or PCB for short is definable as a Common Bus Regenerative Board with a normal Mark V Series assembly version, it actually does not exist as the original Common Bus Regenerative Board manufactured for the Mark V Turbine Control System Series; that would be the related DS200GSIAG1 parent circuit board missing the full three-fold revision table applied to this DS200GSIAG1CBA product offering. The Mark V Series that this DS200GSIAG1CBA Common Bus Regenerative Board has been deemed compatible with is one of the more recently-developed Mark V Series put out by General Electric that features the Speedtronic technology seen in General Electric printed circuit boards since the late 1960s.

Hardware Tips and Specifications

As with any General Electric or Mark V Series printed circuit board, this DS200GSIAG1CBA Common Bus Regenerative board comes standard with its own series of functionality-encouraging hardware components and specifications. The GE Common DC Bus Regenerative Board DS200GSIAG1CBA contains three 40-pin connectors, two 16-pin connectors, and 6 jumpers. The board also has 1 8-pin connector, and multiple test points. The test points in the assembly of this DS200GSIAG1CBA Mark V Turbine Control Series product can be used by a qualified servicer to diagnose the board if the board doesn’t function correctly. All of the various hardware components made useful to the assembly of this GSIA-abbreviated Mark V Series circuit board should receive at least some protective basis from the normal style of PCB coating that is extended across the entirety of the base board of this DS200GSIAG1CBA product offering. Neither of this DS200GSIAG1CBA Common Bus Regenerative Board's functional revisions are considered backwards-compatible, as this DS200GSIAG1CBA PCB's primary functional product revision has a higher grade than its secondary one.

To use this DS200GSIAG1CBA PCB's various test points, it is crucial to first remove all power to the drive and then use a tester to verify that all power is disconnected from the drive; typically this is performed by removing the fuses from the power supply attached to the drive. Once the DS200GSIAG1CBA drive is safe to touch without the potential of electric shock and burn, open the board cabinet and remove the screws that secure the board to the rack. The DS200GSIAG1CBA board is attached to the greater Mark V Series automated drive assembly with four screws in the four corners of the board. To avoid damaging all the boards and components, have a good view of the interior of the cabinet and prevent the screwdriver from scraping against the components or striking them. Use two hands to remove the screws and washers. One hand to turn the screwdriver and the other to hold the hardware. Before you unplug the cables, note where they are attached to the board. You might find it helpful to write down the connectors to which the cables are attached. As outlined by General Electric installation instructional materials, it is crucial to wear a wrist grounding strap while handling this DS200GSIAG1CBA PCB in avoidance of lasting board damage through static electricity.