About the DS200LDCCH1APA

The DS200LDCCH1APA is a Drive Control and LAN Communications Board created by General Electric as part of their Mark V Turbine Control System series. The Mark V is part of the successful Speedtronic line of gas and steam heavy-duty turbine management systems developed by GE. While the MKV is now considered obsolete and is no longer supported by the manufacturer, it is still in active use around the globe. The series uses triple redundant backups on protection parameters and critical controls to increase reliability. The Mark V Series that this DS200LDCCH1APA PCB belongs to is definable as a highly-sought General Electric product series on the greater automated industrial marketplace as it exists as one of the final-developed General Electric product series to make use of the patented Speedtronic control system technology first introduced with the rollout of the Mark I Series in the mid to later 1960s. This particular DS200LDCCH1APA printed circuit board product offering is actually not the originally-developed product of its specific Mark V Series functionality; that would be the DS200LDCCH1 parent Drive Control and LAN Communications Board missing this DS200LDCCH1APA PCB's three significant product revisions.

Hardware Tips and Specifications

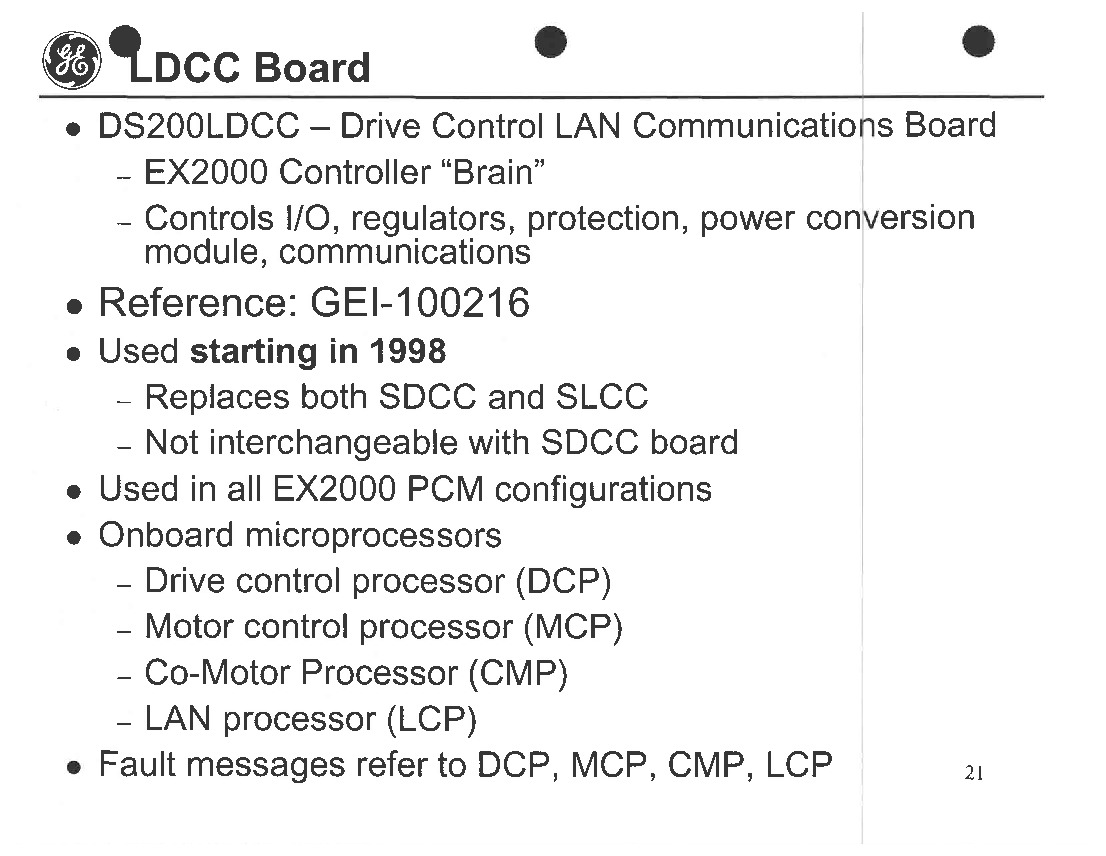

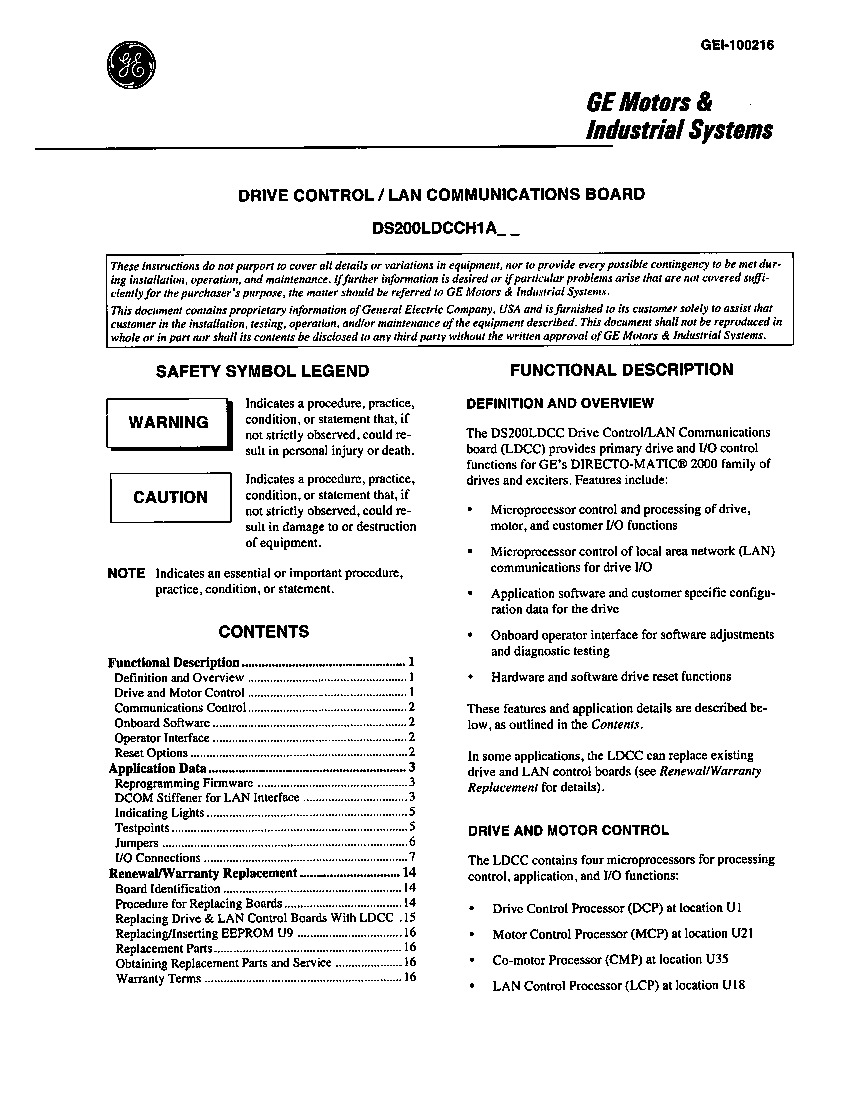

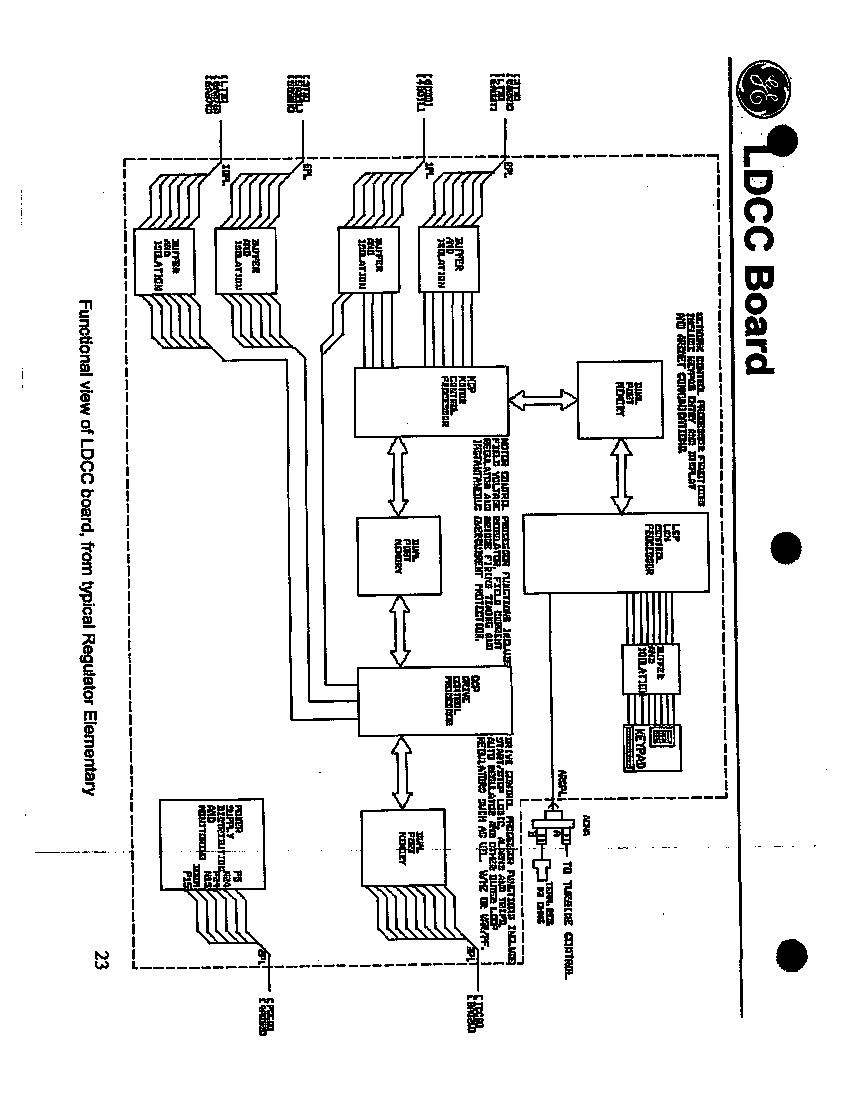

As a Mark V Series product available to our new and extended reconditioned inventory here, this DS200LDCCH1APA PCB's intended functionality is introduced with its normal Mark V Series' assembly's acceptance of a specialized set of hardware components and component specifications. The DS200LDCCH1APA is able to function within exciters or drives that are a part of GE’s DIRECTO-MATIC family. The board provides primary drive functions and I/O control functions. The board is built with four microprocessor chips, including a drive control processor (DCP,) a motor control and co-motor control processor (MCP and CMP,) and a LAN control processor (LCP.) It also has six flash PROMS and an EEPROM that contains space for field-adjustable parameters. The DS200LDCCH1APA is capable of processing Inputs/Outputs through its LAN control processor from five different bus systems. These include C-bus, CPL, Genius bus, DLAN, and DLAN+. Since some of these bus systems need a separate interface board to complete I/O transfer, the DS200LDCCH1APA is designed to connect to an auxiliary board, which mounts to four standoffs located in the upper right quadrant of the board. All ten I/O connections located on the DS200LDCCH1APA are vertically mounted. Ten connections are male. One is female.

The DS200LDCCH1APA has fourteen wire jumpers and ten Berg-type jumpers. There are eight TP label-indicated test points located on the board. The board is built with a sixteen character operator interface module, which is located in the upper left quadrant. This interface allows the user to do diagnostic testing and to make software adjustments. The board includes a ten-light LED strip which can be programmed to indicate drive variables and/or fault codes. Generally, this DS200LDCCH1APA PCB's voltage suppression and protection is handled by its normal Mark V Series assembly's adoption of a series-standardized selection of hardware components and component specifications including various styles of capacitors, resistors, diodes, and specialized integrated circuits. This DS200LDCCH1APA printed circuit board product offering from GE is not surrounded by a plethora of pertinent instructional documentation online; most likely as symptom of its legacy product status. With this being true, the DS200LDCCH1APA functional product number serves as an important supplementary source of DS200LDCCH1APA PCB hardware information; coding for specific details in a series of consecutive functional naming segments. For instance, the DS200LDCCH1APA functional product number begins with the dual-functional DS200 series tag highlighting the product's normal Mark V Series assembly as well as its domestic original manufacture location. Some of the other relevant hardware traits revealed through this DS200LDCCH1APA PCB's functional product number includes its LDCC functional product acronym, conformal PCB coating style, and finally its full three-fold product revision history.