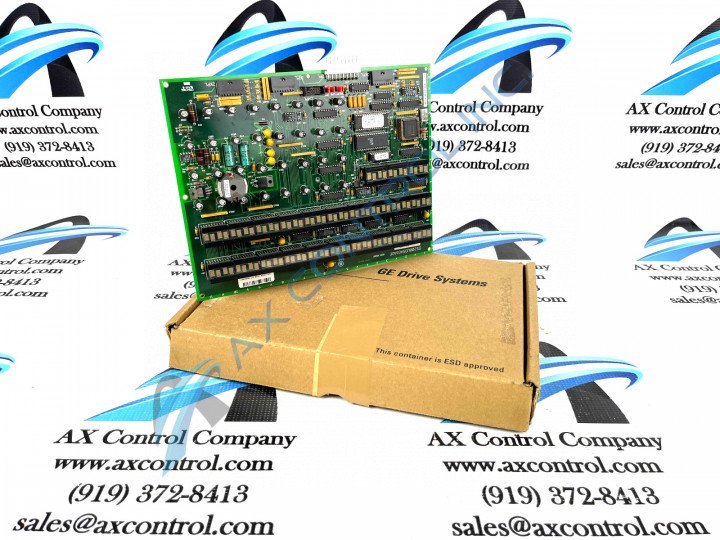

About the DS200UDSAG1

As indicated just above, this DS200UDSAG1 printed circuit board product offering was originally manufactured by the trusted automated industrial retailer General Electric, specifically for placement in their Mark V Turbine Control System Series. The Mark V Series that this DS200UDSAG1 printed circuit board or PCB for short was originally produced for has specific applications in the control and management systems of wind, steam, and gas turbine automated drive assemblies, as hinted at in its above-included full extended series name. This DS200UDSAG1 product offering's greater Mark V Series is considered to exist as a now-obsolete General Electric legacy product series, as it was discontinued for manufacture in the many years following its initial conception. This DS200UDSAG1 product offering's greater Mark V Series, while a now-obsolete legacy General Electric product series, additionally exists as one of the final series to utilize the Speedtronic control system technology first used and patented alongside the rollout of General Electric's Mark I Series in the later 1960s. This DS200UDSAG1 Excitation Board is the original, base-revised version of its intended functional Mark V Series role, as evidenced by its DS200UDSAG1 functional product number's lack of any trailing revision-indicating digits.

Hardware Tips and Specifications

This DS200UDSAG1 product offering's Excitation Board functionality is introduced through its internal assembly's acceptance of a unique series of hardware components and component specifications. The GE Excitation Board DS200UDSAG1 features one 1 80196 microprocessor and several erasable programmable read-only memory (EPROM) modules. The GE Excitation Board DS200UDSAG1 also is populated with 21 4-character displays and 32 LEDs. The board is also populated with several capacitors that during normal processing, do not require any special consideration. The capacitors store high-voltage current and release in when needed for operation of the board. As this DS200UDSAG1 printed circuit board exists as a member of a now-obsolete Mark V legacy product series, many of its original instructional manual materials and datasheets have been made unavailable online by the original General Electric manufacturer. With this in mind, the General Electric-crafted DS200UDSAG1 functional product number becomes a primary source of original DS200UDSAG1 Board hardware component and specification information, as it reveals these details in a series of specific functional naming chunks. For instance, the DS200UDSAG1 functional product number begins with the DS200 series tag dictating this DS200UDSAG1 PCB's normal Mark V Series assembly as well as its domestic location of original manufacture. Some of the other relevant details revealed in its functional product number include this DS200UDSAG1 PCB's:

- UDSA functional product abbreviation

- Group one Mark V Series product grouping

- Normal PCB protective coating

When a servicer is performing the maintenance procedure on the drive or if the board is being replaced, you must observe special guidelines concerning any board that is populated with capacitors. When power is removed from the drive, prior to removing the board, the capacitors might have high-voltage current residing in them. This could easily cause injury to the servicer. It might result in electric shock or burns. It could also lead to damage to components if the high-voltage current accidentally enters the components. After 30 seconds the high-voltage current exits the capacitors and the board is then safe to touch. For this reason, wait 30 seconds before you begin the replacement procedure. The board must be installed in a location that enables the drive operator to view the LEDs and the 4-character displays. For that reason, before you remove the old board note where it is installed and install the replacement board in the same place. The board is 8.5 by 11-inches in size and has 1 hole in each corner for screws that secure the board in the rack. When you remove the old board save the screws and use them again to install the replacement board.