❮

❯

IS200IIDAG1ABB

- 4.92 (25)

- Click a star to rate this product

- 4.92 (25)

- Click a star to rate this product

The IS200IIDAG1ABB Direct Current Innovation Card was made for General Electric's Mark VI Turbine Control System Series.

AVAILABILITY:

IN STOCK

SHIPS TODAY

- Part Number: IS200IIDAG1ABB

- SKU: IS200IIDAG1ABBGBTC

- Manufacturer: GE Boards & Turbine Control

- Series: Mark VI IS200

IS200IIDAG1ABB Technical Specifications

| Original Manufacturer | GE Drive Systems |

| Series | Innovation Series |

| Part Number | IS200IIDAG1ABB |

| Functional Acronym | IIDA |

| Functional Description | DC Direct Current Innovation Card |

| PCB Coating | Normal Coating |

| Primary Functional Revision | A |

| Secondary Functional Revision | B |

| Artwork Revision | B |

About the IS200IIDAG1ABB

The IS200IIDAG1ABB is a PCB component designed by GE Drive Systems as a part of a General Electric system; specifically the Mark VI Turbine Control System Series. This Component PCB is relatively limited in terms of the amount of pertinent manual information about it available online, but is generally classified as a member of a steam/gas turbine management series, which have been implemented in various iterations and GE shell companies since the 1960s. The Mark VI is one of the last systems released in this series, and also one of the most advanced. The IS200IIDAG1ABB is a narrow board that is used as a DC Direct Current Innovation Card within the greater drive assembly. The Mark VI Series that this IS200IIDAG1ABB product is considered a component member of represents quite the notable functional upgrade upon the previously-existing Mark V Turbine Control System Series of the same full extended series title, as it expanded the turbine applications to accept the alternative energy-friendly wind turbine automated drive functional application.

Hardware Tips and Specifications

The base board of the IS200IIDAG1ABB is densely-laden with a series of specific components that includes Ethernet communications, a PC-based Operator Interface operating on a Windows platform, and a Central Control Module with triple redundant back-ups on almost all critical control and protection parameters. While the board is component dense, it is important to note it does not have any adjustable hardware, integrated circuits, or fuses. The board has a conduction sensor located in each of the front corners. The back corners of the board feature factory-drilled holes for installation purposes. As with many Mark VI Speedtronic printed circuit board, components are marked with reference designators. In addition to these standard industry-recognized reference labels, the IS200IIDAG1ABB board is marked with codes like “6BA02.” The IS200IIDAG1ABB is essentially built with three long lines of components. The first line consists of fifteen two-position terminal strips placed at an angle. The second line of components begins with a two-position terminal strip, then has five 4-position header connectors, followed by twelve 8-position header connectors. This second line finishes with another single two-position terminal strip. The last line of components includes five stab-on connectors followed by twelve 2-position header connectors.

Installation Tips and Specifications

Our team will treat the IS200IIDAG1ABB as a static-sensitive board during handling, packaging and shipment. It is important to observe a series of safety precautions when handling the installation of this IS200IIDAG1ABB module, as similar General Electric Speedtronic series products have been known to carry dangerous, potentially lethal surface voltages. Generally speaking, this involves the use of a General Electric-recommended grounding strap for the entirety of the installation process. The knowledgeable PCB component installer recognizes the existence of potentially lethal surface voltages on the face of the IS200IIDAG1ABB or any PCB module, and always powers down the greater drive assembly prior to attempting any installation. Installation procedures may be found in publication like manuals, user guides, or data sheets from General Electric that reference the IS200IIDAG1ABB part number, although something of a deficit of information for this specific product is available online.

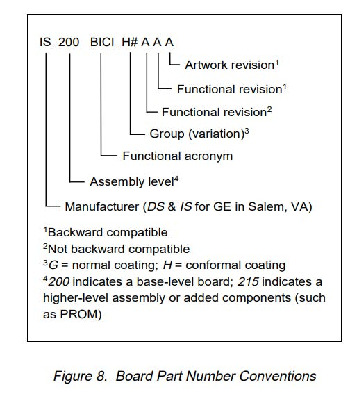

It is important to recognize the multiple functional revisions and singular artwork revision inherent to the IS200IIDAG1ABB model printed circuit board before making any ultimate purchase decisions. These revisions, which may greatly alter both the performance specifications and physical dimensions of the IIDA module, are decipherable through an analysis of this product's part number. The final three digits of the IS200IIDAG1ABB product number, as described above in the manuals tab's IS200IIDAG1ABB Part Number Breakdown, represent three revision versions made to the original IS200IIDAG1 parent product. These revisions can be defined as a Functional Revision 1 graded at an A, a Functional Revision 2 which achieved a B rating, and finally an artwork revision rated at a B.

Frequently Asked Questions about IS200IIDAG1ABB

Are this IS200IIDAG1ABB product's factory-drilled holes on the corners of this printed circuit board insulated?

How does your AX Control service team treat the IS200IIDAG1ABB as a static-sensitive board during handling, packaging and shipment?

Can you make a repair to my IS200IIDAG1ABB?

Reviews For IS200IIDAG1ABB

Internal Review

(5.0)While this seems to be a well-supported printed circuit board, considering its three-fold revision history; the Direct Current Innovation Card IS200IIDAG1ABB prospective buyer may encounter barriers to purchase in its relatively insufficient availability of pertinent manual material online. With this being said, it is generally accepted as a part of the General Electric Innovation Series, considering its correct functional description as a Direct Current "Innovation" Card. Available now for both repair and replacement here today. - AX Control Lead Technician

Repair Services For IS200IIDAG1ABB

| Type | Lead Time | Price | Action |

|---|---|---|---|

| Repair Service | 1-2 weeks | $225 |

Our highly skilled technicians can repair your IS200IIDAG1ABB. All of our repairs come with a 3 Year AX Control Warranty. Please contact us for additional information about our repair process. To receive the repair pricing and lead time listed above please process your repair order via our website. The following repair options may be available upon request:

- 48-72hr Rush Repair

- Detailed Repair Reports

- AX Control Certificate of Warranty

AX Control Warranty Info

All products we sell are backed by our unparalleled warranty. A warranty certificate will be provided with your order upon request.

| All PLCs, HMIs, and Turbine Control Boards: | 3 Years |

| All AC/DC and Servo Drives: | 2 Years |

| All Motors: | 1 Year |

IS200IIDAG1ABB Manuals, White Papers, Data Sheets, and Troubleshooting

You may also like...