About the IS2020DRLYH1A

The IS2020DRLYH1A is a terminal board designed by General Electric shell company GE Industrial Systems for use within the greater Mark VI turbine control series. This particular PCB or printed circuit board is modified through the inclusion of a singular revision; a revision rated at an "A" grade. This Contact Relay Output Terminal Board's special assembly type, along with the aforementioned singular revision, may increase the board assembly's overall performance specifications as well as its general dimensions. The Mark VI Turbine Control System Series that this particular IS2020DRLYH1A Contact Relay Output Terminal Board PCB product offering belongs to, as partially indicated through its full extended GE product series title, exists with a set of specific functional applications in the control and management systems of General Electric-compatible gas, steam, and wind turbine automated drive assemblies. Thus, the Mark VI Series has to be considered something of a stark upgrade in comparison to the earlier-released Mark V Turbine Control System Series of a similar full extended series name, as the Mark V Series before possesses a more restricted functional application range in gas and steam-based environments alone.

Hardware Tips and Specifications

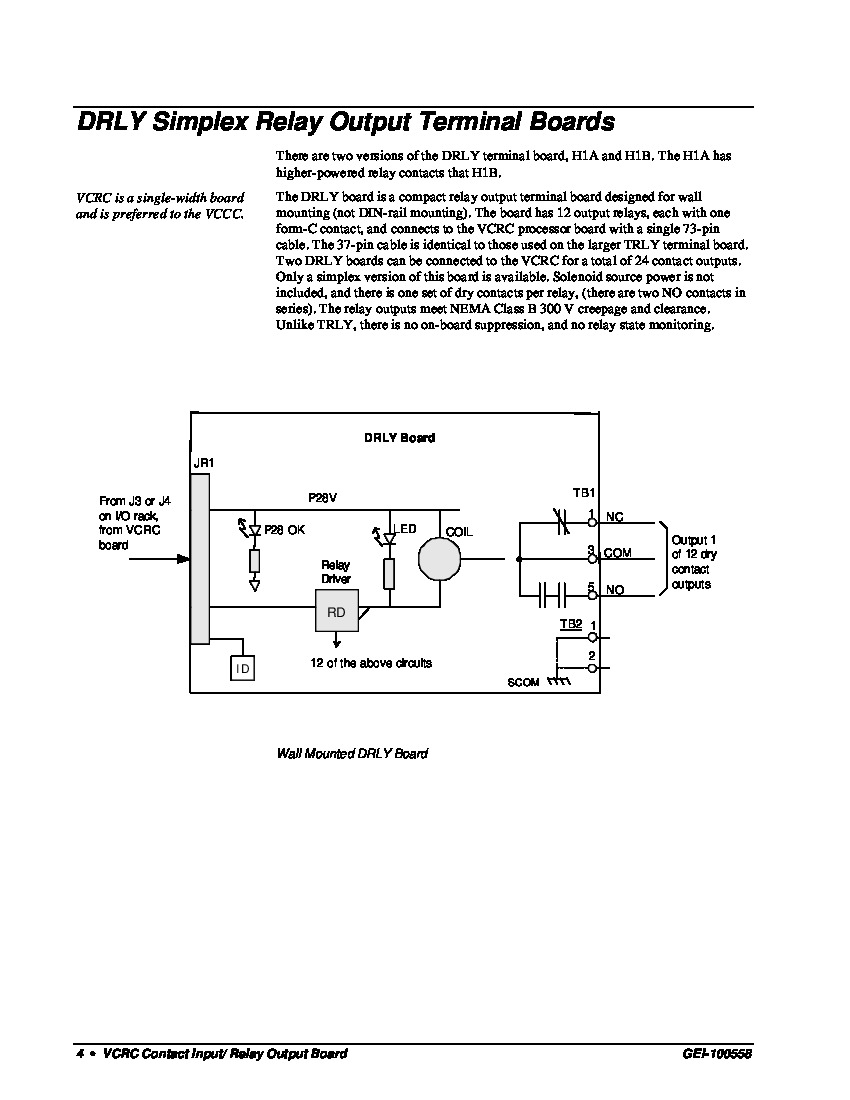

A number of important tips and specifications exist for this IS2020DRLYH1A model of printed circuit board. To begin, this Contact Relay Output Terminal Board makes use of numerous output relays affixed to its base board; 12 output relays in total. Each of these output relays have one form-C contact apiece, and they all connect to the necessary VCRC processing board through the use of a 37-pin cable. This 37-pin cable is exactly the same as the cables that features on the base board of the much bigger TRLY circuit board, also from the Mark VI Speedtronic series. Considering the fact that solenoid source power is not available to the IS2020DRLYH1A; it should come as no surprise that this PCB has one set of dry contacts per relay. Only a simplex version of this compact relay output terminal board is available, as of this moment, although multiple revised versions of the parent IS2020DRLY board exist. One such revision exists in this "H1A" model, which indicates a general purpose relay output terminal with ratings spanning across the majority of relevant applications. Please don't confuse this IS2020DRLYH1A revised PCB with the IS2020DRLYH1B model; the "H1B" model was designed sealed and with smaller contacts for Class 1 Div. 2 applications.

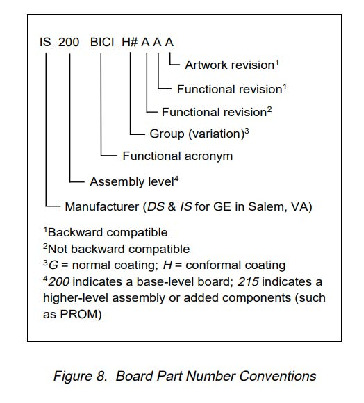

While several significant revisions may impact the performance specifications of your IS2020DRLYH1A model PCB, this Mark VI Speedtronic Series product is also altered through its special assembly type. The IS2020DRLYH1A is supported a metal plate assembly, which is intended to be mounted on a wall. This metal backplate assembly asserts the DRLY board's status as a non DIN-rail-mounted PCB. Outside of this assembly, the DRLY board has 12 relay outputs; directly wireable to odd-numbered screws on the terminal blocks. These Euro-Block type terminal blocks are created to be plugged into the board's intuitively-numbered receptacles. Two separate screws exist on TB2 for SCOM or chassis ground connection. Before making a purchase of this IS2020DRLYH1A printed circuit board, it is important to acknowledge that this Mark VI Speedtronic model does not come standard with the shield termination strip reminiscent of so many other similar series model PCBs. All of the aforementioned hardware component parts are protected beneath a thorough and completely-layered protective circuit board coating. The type of coating that protects this Contact Relay Output Terminal Board can be discovered through a careful Part Number Breakdown, as outlined in the one available above through our manuals tab. The "H1" portion of the IS2020DRLYH1A product number designates this PCB as both conformally-coated in terms of PCB protection, as well as a member of the Group 1 Mark VI Speedtronic Series grouping. Conformal PCB coating, while significantly thinner than the alternative normal-style coating; covers the entirety of the surfaces of every PCB component, in a chemically-treated application.