About the IS200TREGH5B

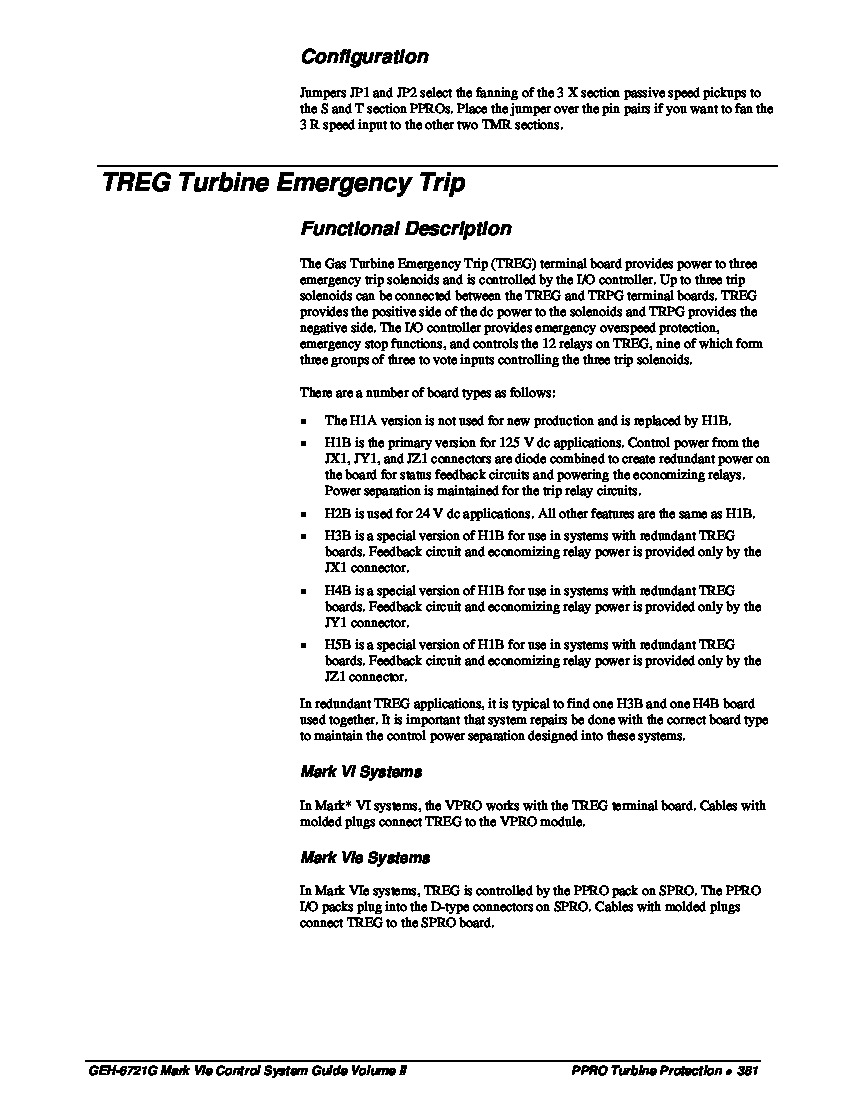

The IS200TREGH5B Gas Turbine Emergency Trip Board has made as a part of the greater Mark VI Speedtronic series, and therefore remains compatible with a slew of other Mark VI Speedtronic products. One such product is the VPRO protection module, which is entirely responsible for controlling the TREG PCB. The only connections that exist between this TREG printed circuit board and the VPRO protection module are its trip solenoid connections as well as its J2 power cable. A servo valve clamp function is supplied in simplex systems, and extends from the J1 connector through to the TSVO associated terminal board. While the J1 connector is relevant in terms of VPRO module connections, a set of other crucial connectors exist, stemming from the base board of the IS200TREGH5B.

The TREG connectors JX1, JY1, and JZ1 all have individual ID devices for I/O controller interrogation purposes. These connectors all have specialized voltage functions, as outlined in original General Electric Instructional Manual Material. For example, the JZ1 connector attached to the TREG PCB provides feedback circuit and economizing relay power to the greater drive assembly. The ID devices associated with these crucial connectors are read-only chips coded with a series of specific information, including the TREG board's serial number, board type, plug location, revision history, and plug locations. While a number of hardware components and connectors need to be emphasized before making a purchase decision of this TREG Gas Turbine Trip Board, it remains equally important to understand the function of the board itself. The IS200TREGH5B provides:

- power for up to three emergency trip solenoids

- positive dc power to greater assembly solenoids

- additional trip solenoid support and processing power through relays