About the IS200WEMAH1A

The IS200WEMAH1A is a Mark VIe Series component manufactured by GE; more specifically by General Electric shell company GE Energy. The Mark VIe was one of the last gas/steam turbine management systems created and released under the Speedtronic name, and in this instance, provides control system options for a range of compatible Gas, Steam, and Wind Turbines. The Mark VIe Turbine Control System Series that this IS200WEMAH1A product offering belongs to has to be considered a highly-sought GE Mark product series generally, as it is one of the final-developed GE Mark product series to make use of the patented Speedtronic control system technology first seen in the Mark I Series in the later 1960s. This particular IS200WEMAH1A Mark VIe Series printed circuit board was designed intended to be used in wind turbine control applications specifically, and carries a singular functional revision rated at an "A" grade. This A-rated revision is a functional revision as it makes improvements to the overall functionality of the IS200WEMAH1A board, without sacrificing for durability or aesthetic purposes. The singular functional revision present on the IS200WEMAH1A board modifies it from the original IS200WEMAH1A parent board, as mentioned above.

Hardware Tips and Specifications

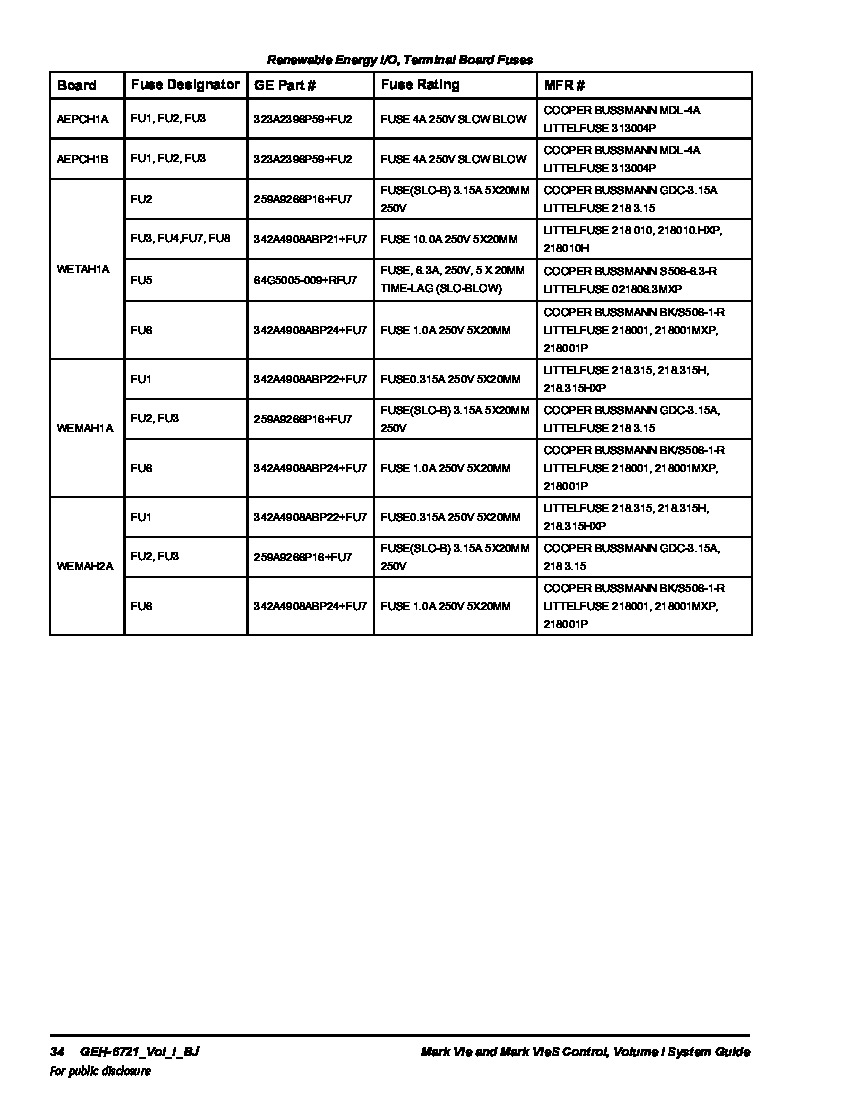

The IS200WEMAH1A is a relatively large, component-dense board. The board has one large and one small transformer. The center of the board is designed to accept an auxiliary board and has four standoffs mounted to the board to support this board if or when it is installed. Two vertical plugs are located near these standoffs for power/communications for the daughterboard. On the opposite side of the auxiliary board location, there exists a line of resistors marked “Estop” and DIN01 through DIN33. The WEMA-abbreviated IS200WEMAH1A board makes use of 27 total digital inputs, 2 analog thermistor temperature sensor inputs, 9 relay contact outputs, and 3 separate solid-state relay outputs. The IS200WEMAH1A;s board assembly includes four terminal strips. These terminal strip components are located side-by-side along one board edge, and are paired with fifteen total relays/contactors. The board has nine heat sink components, most of which are located next to their corresponding relay components. Other components obvious on the base board of the IS200WEMAH1A include six fuses, one switch component, several high voltage electrolytic capacitors as well as other capacitors, terminal contacts, and resistors, including metal film and CCR resistors. The three different fuse types included in the IS200WEMAH1A board assembly are:

- LITTELFUSE 218.315, 218.315H,218.315HXP

- COOPER BUSSMANN GDC-3.15A,LITTELFUSE 218 3.15

- COOPER BUSSMANN BK/S506-1-RLITTELFUSE 218001, 218001MXP,218001P

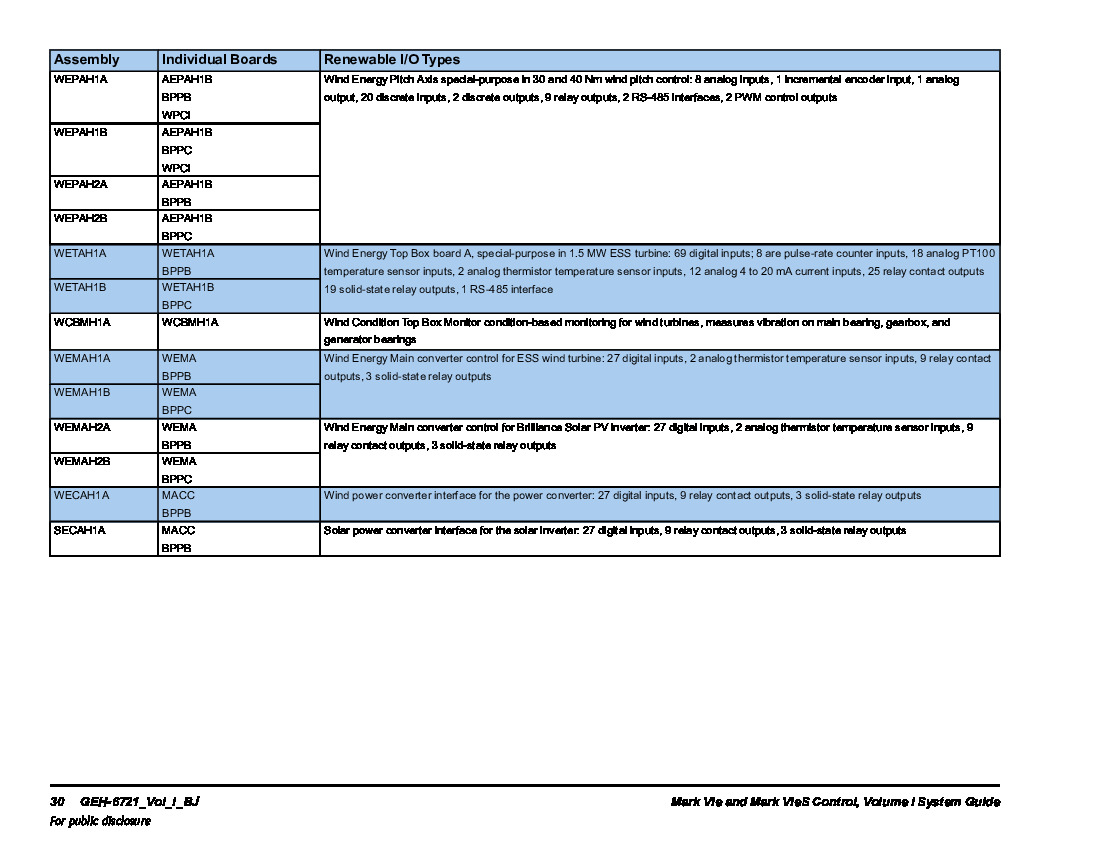

In terms of connector types, this WEMA-abbreviated board has two vertical pin header connectors, three black plugs (P2, P5, and J7) and 18 white plugs that vary from 2-position plugs to 18-position plugs. As indicated in the IS200 series tag present in the IS200WEMAH1A board's individualized product number, this model PCB does not make use of any special assembly type, although it is important to note that its singular functional revision may alter the factory-defined performance specifications or dimensions of the PCB. This IS200WEMAH1A device is a General Electric Mark product series offering, which means that it will be followed online by a characteristic lack of originally-printed instructional manual materials. With this being the case, the IS200WEMAH1A functional product number itself can be considered a primary source of IS200WEMAH1A Board hardware component details, as it indirectly describes this IS200WEMAH1A product's WEMA functional product acronym, conformal PCB surface coating, and A-rated primary functional revision among other facts. This IS200WEMAH1A device's existing instructional manual documentation reveals this IS200WEMAH1A device's renewable I/O types to be the Wind Condition Top Box Monitor condition-based monitoring for wind turbines and the vibration measurement on main bearing, gearbox, and generator bearings I/Os.