About the IC800VMA072

The IC800VMA072 is a 750-Watt servo amplifier that belongs to the VersaMotion series manufactured by GE Fanuc. In addition to its 750-Watt power rating, it has a 2.39 torque rating and a rated speed of 3000 RPM. It has a built-in dynamic brake having 2500 ppr/10000 CPR Resolution/Quadrature Feedback counts. The user has the option to use position, velocity, or torque control modes. IC800VMA072 features both Torque Limit Operation and Feed Forward Compensation. The IC800VMA072 is equipped with a convection cooling system. The gear ratio of this amplifier is N/M, where N is 1~32767 and M is 1:32767. This IC800VMA072 amplifier is capable of withstanding a 5% frequency fluctuation from its standard 50-60Hz frequency rating. Digital I/O set-up, monitoring and force are all supported by this amplifier. Each I/O point can be individually set to one of the built-in functions (45 digital input functions and 11 digital output functions).

IC800VMA072 has three phase or single phase 220-VAC with 50/60 Hz frequency. There are power and encoder connectors for connecting the motor to the amplifier. It has dual control mode capability with standalone single-axis position control mode for simple point-to-point motion control and electronic gearing with user-defined ratio. When it has no load, it’s acceleration time is 10ms. Additionally, this amplifier also contains the External JOG function. It stabilizes at low speed. When operating at 1 RPM, the IC800VMA072 is extremely accurate, with less than 0.5% error. IC800VMA072 has a simple stand-alone point-to-point positioning control built-in function with 8 internal stored position settings (positions can be changed over Modbus for greater application flexibility).

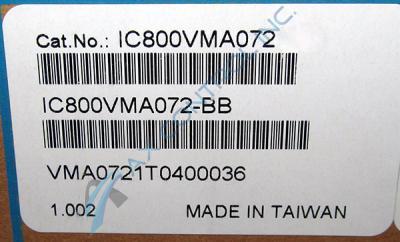

IC800VMA072 uses the IC800VMCPXXX (where xxx can be 030, 050, 100, 200 for 3m, 10m, 20m respectively) power cable and the IC800VMCEXXX Encoder cable. The module has the following connector ports: CN1 I/O connector, CN2 Encoder connector, CN3 Communication connector, AC Power connector, Motor Power connector and External Braking Resistor connector. It has communication interfaces RS-232/RS-485/RS-422 that can be used for reading and writing parameters from Machine Edition or updating stored position set points from a host controller. IC800VMA072 contains the feed step control function with the position teaching function. The machine also has calculation tools to make conversions into different units more convenient for the user. It also has screens to show alarm history and monitor diagnostics with three channel digital oscilloscope to display and record drive status online.

IC800VMA072 support the motors IC800VMM07LNKSE25 and IC800VMM07LBKSE25. IC800VMM07LNKSE25 is a low inertia 2500 PPR encoder with straight shaft, Key and Oil Seal. IC800VMM07LBKSE25 is a low inertia 24VDC Holding Brake with 2500 PPR Encoder. Motor feedback is provided by 10,000 quadrature counts per revolution for a resolution of 0.036 degrees of a motor revolution. They provide precise feedback control and high-speed calculation functions incorporating DSP (Digital Signal Processor) technology and are intended to drive three-phase permanent magnet synchronous motors (PMSM) to achieve precise positioning by means of accurate current output generated by IGBT (Insulated Gate Bipolar Transistor).