About the 239-AN

According to the extensive order codes list in the GEK-106613C 239 Motor Protection Relay Instruction Manual, the 239-AN model has a single, isolated analog output that can operate on three different milliamperes ranges which is 4-20, 0-1, or 0-20. There are also programmable output parameters which include adjusting the phase current temperature for RTDs 1, 2, and 3, changing the thermal capacity, and changing the percentage of the full load. As previously mentioned the analog output range can be selected for the user’s needs. When the relay is being used in processes where loads of the motor are varies and are typically operated at almost the motor’s full load it is vital to know if the relay will be close to tripping so the load can be adjusted accordingly.

One of the specifications of the 239-AN relay is start protection. Occasionally start protection is not required and can be disabled on the relay. If the setpoint on the relay is set to yes the model will go directly into overload curves and run conditions will be employed to protect the connected load model. This specific setpoint can also be used with a switch input, the disable starts must be set to yes if wishing for the start protection to be defeated when the conjoining switch input is closed.

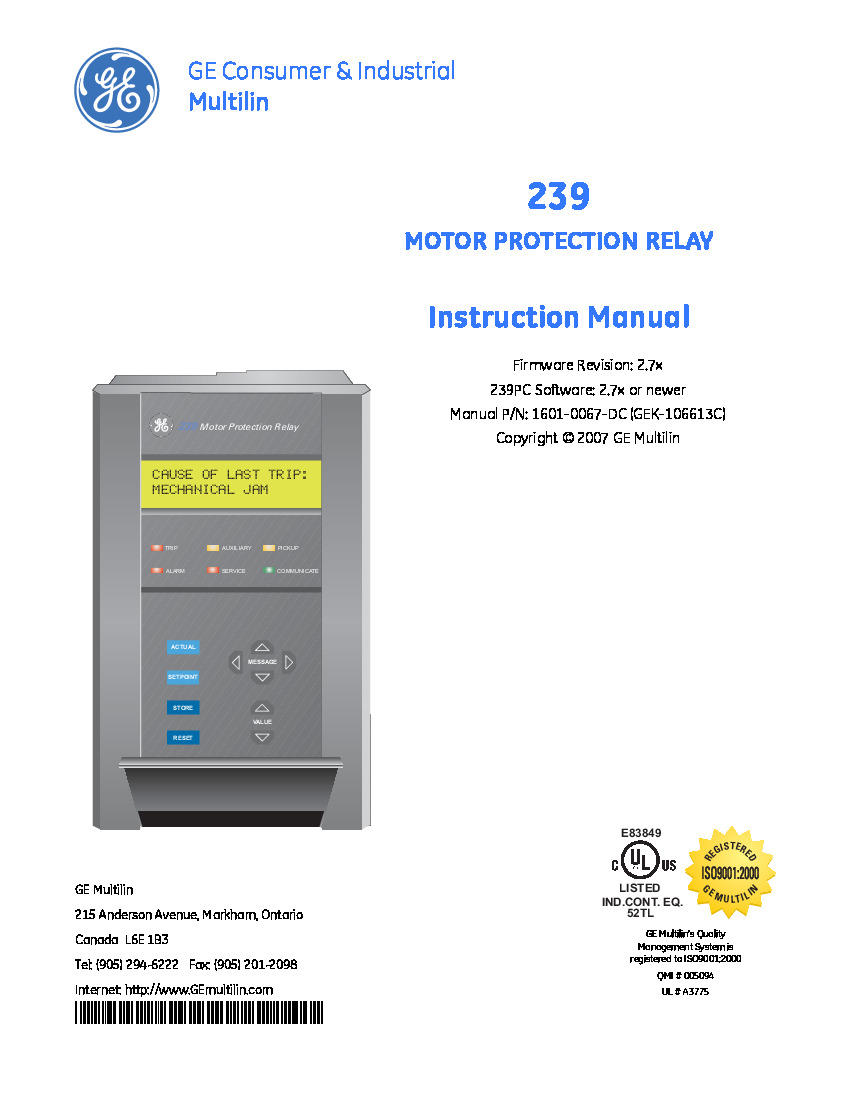

One of the programming features of the 239-AN relay is the mechanical jam. The function of the mechanical jam is that it will primarily be used for protecting attached equipment such as gearboxes, saws, compressors, and pumps. Please note that it is often recommended that an immediate trip occurs in the event of a locked rotor during the operation of the device.