Frequently Asked Questions about 239-RTD-AN-H

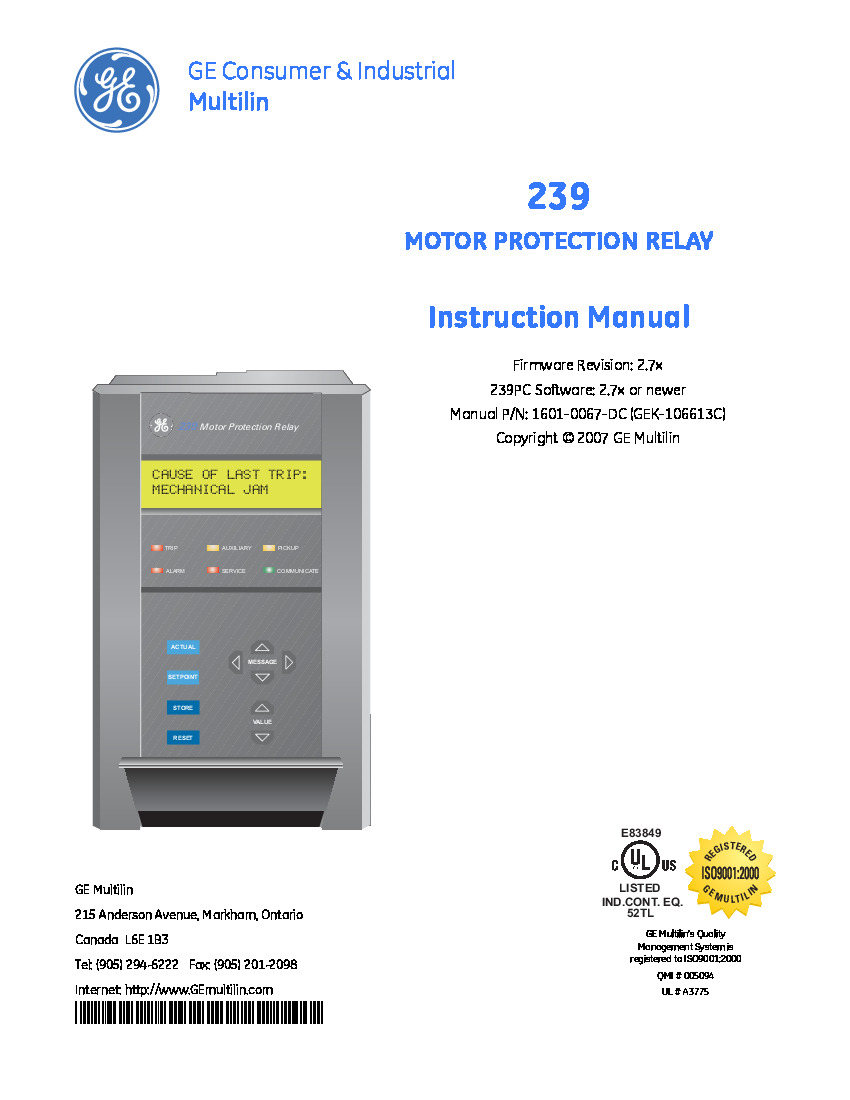

What differentiates the GE Multilin 239 motor protection relay from the motor protection relay with the 239-RTD-AN-H options for the order code?

The difference in the 239-RTD-AN-H order code from the parent motor protection relay is that the H order code signifies the additional feature of the harsh environment conformal coating.

What are the analog options for the GE Multilin 239-RTD-AN-H?

The analog options for the GE Multilin motor protection relay with part number 239-RTD-AN-H come in three options: 0-1 mA, 0-20 mA, and 4-20 mA. Output relays for the voltage are either resistive or inductive.

What are some faults that the Multilin 239-RTD-AN-H can protect against? What are typical applications for this motor protection relay?

Typical applications and reasons for installation of this relay are to protect against some common mechanical faults. For example this product can detect a closed discharge valve or loss of suction. This product can also protect against mechanical jam and protect from operator fault by using a thermal memory lockout feature. The GE 239-RTD-AN-H has these and other features making this product an ideal choice for electrical protection of motors.