This article will focus on the qualities of RTDs vs Thermocouples and their typical applications and principles.

Measuring temperatures in industrial engineering is a key part of monitoring the operation of the various mechanical, electrical, and electronic systems, determining their performance, and evaluating their health.

Likewise, in chemical processes, temperature and heat control may be crucial in achieving the desired end product. Additionally, the same applies to welding, heat treatment processes, industrial ovens used for plastic shrinking, and a wide range of other possible applications. That said, measuring temperatures is neuralgic in a wide range of engineering operations, and doing so with accuracy and precision is equally important.

While there are many types of thermometers that can be used for measuring temperatures including the familiar “mercury” thermometers, the bimetallic, and the vapor pressure thermometers, those that are most commonly and widely used in the industrial environment are the resistance temperature detectors (RTD) and the thermocouple devices. Both of these thermometer types have their respective advantages and drawbacks, and they are both suitable and valuable for a distinctively different set of applications.

Working Principle of Resistance Thermometers (RTD)

The RTD temperature sensor is based on the temperature dependence of the electric resistance of metals. As the temperature increases for metal, so does its electrical resistance. Of course, there’s an intrinsic coefficient of resistance for all materials, and a positive value for this coefficient makes specific materials better than others for the measurement element role. With nickel and platinum, for example, there is near-perfect linearity that is introduced by their respective coefficients, resulting in high accuracy and precision across repeated measurements. Moreover, nickel and platinum are generally chemically stable and extremely resistant to corrosion.

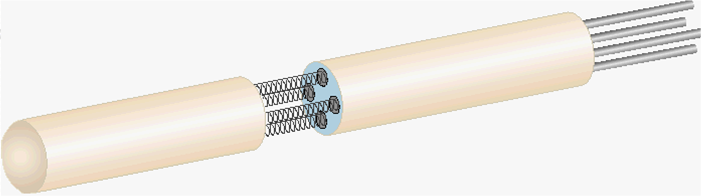

For this measurement method to work, the sensor needs to house the measurement element and deduce the temperature by measuring its resistance. The elements can constitute thin layers of platinum or nickel on a ceramic plate, metallic wire wound around an insulating core, coiled and strain-free elements, and various other types of specialized implementations.

To ensure that the correlation between resistance and temperature is specified for all RTD manufacturers, there is even a standard (IEC 60751:2008; ASTM E1137) that determines the numerical relationship for platinum resistance elements.

Pros of RTDs

- High accuracy in the measurements (down to 0.1 OC)

- High precision in repeated measurements

- Wide temperature measurement range

- Long-term drift is minimal

- Immunity to electrical noise and magnetic interference

- Competitive expected lifespan on lower to mid-temperature ranges

- Connection wires are generally inexpensive

- Relatively good mechanical robustness

- Linearity in the measurements

- Can measure temperatures below zero (minus 200 degrees Celsius)

Cons of RTDs

- The larger size may be an insurmountable problem in some applications

- Require proper calibration before installation/use

- Generally costs more than thermocouples

- The measurement times may be a bit longer (1 to 50 secs)

- Doesn’t support measuring temperatures above 850 degrees Celsius

- Susceptible to vibration damage

- Needs power supply to operate

- Cannot measure surface temperatures

Common Applications of RTDs

RTD sensors are used anywhere where the time required for the measurement isn’t a critical factor, but at the same time, accuracy is. This includes air conditioning units, refrigerators, stoves, lab ovens, and various types of micro-electronics, leveraging their electromagnetic immunity. Other areas of application involve air, gas, and liquid temperature measurement that is impossible with other types of thermometers. That said, plastic processing, petrochemical processing units, and textile production locations generally use RTDs extensively.

Working Principle of Thermocouples

The thermocouple’s working principle is based on the thermoelectric effect, which enables the measurement of temperature differences through the electric voltage differences and vice versa. As the name suggests, this sensor couples two thermoelectric materials of different conductivity, which results in the generation of voltage at a specified temperature range.

By knowing the correlation between temperature values and voltage values for specific metallic couples, we can build thermocouples that work on different temperature ranges and deduce the temperature and the measurement point. For example, some common metal pairs are two different nickel alloys, tungsten and rhenium alloys, gold and iron alloys, platinum and rhodium alloys, or platinum and molybdenum alloys. For this measurement method to work, the two wires need to start from a “cold” reference junction and get coupled on the “hot” measurement point.

Pros of Thermocouples

- Is very inexpensive compared to RTDs

- Can measure very high temperatures (up to 2300 OC)

- Is small in size, so it can fit in hard to reach places

- It can measure surface temperatures

- It features excellent mechanical robustness

- Won’t be damaged by vibrations

- Measurement/reaction times are very short (0.1 – 10 secs)

- Requires no power to operate

Cons of Thermocouples

- Prone to reference junction temperature estimation errors

- Not very accurate measurements (0.5 OC at best)

- Aged instruments are worthless and cannot be re-calibrated

- Cannot measure temperatures below 200 degrees Celsius

- Measurements are not linear

- Variable accuracy degradation rate with time

- Susceptible to electrical noise

Common Applications of Thermocouples

In general, we see thermocouples wherever the need for accuracy isn’t that compelling. Moreover, and thanks to the fact that thermocouples can measure particularly high temperatures, we see them deployed in the steel industry. Gas appliance safety is also a field where thermocouples are extensively used thanks to their small size and robustness, and also because they are so quick to give a reliable measurement, allowing for short reaction times. Finally, we see thermocouples used in process and power plants, and close to arrangements that can produce vibrations.

Comparison Overview

| Property | RTD | Thermocouple |

| Temperature Range | -200 to 650 OC | 180 to 2400 OC |

| Measurement Accuracy | 0.01 to 1 OC | 0.5 to 5 OC |

| Reaction Times | 1 to 50 seconds | 0.1 to 10 seconds |

| Diameter Size | 3 to 7mm | 0.5 to 2mm |

| Long-Term Stability | Very Good | Depends |

| Linearity | Yes | No |

| Powering Requirements | Yes (10mA) | No |

| Need for Calibration | Yes | Reference Junction |

| Expected Lifespan | Good | Depends |

| Electrical Noise Interference | No | Yes |

| Ability to Withstand Vibrations | No | Yes |

| Cost (generally) | Expensive | Inexpensive |

How to Pick the Right One For You

Of all the factors that you will have to consider before you make your choice, there are four fundamental factors that determine whether a particular thermometer type is suitable for the intended application or not. These are the temperature range, the size of the sensor, the accuracy of the measurements, and finally, the response time.

- First, consider the temperature ranges you need to cover. If they are between 200 and 500 degrees Celsius, you may pick either type. If not, you’ll have only one way to go.

- Secondly, if you are looking to implement a safety system, fast response is key, so the thermocouple is the only choice that makes sense.

- Accuracy is the third essential consideration to bear in mind as some applications absolutely require it. Some thermocouples can sport measurement inaccuracies that are as bad as +-5OC, and this would be catastrophic when monitoring chemical processes or when trying to keep fresh produce cool.

- Size is the fourth fundamental element to consider, and while the need for more space can often be accommodated, sometimes, an RTD just won’t fit in the desired location.

Should You Go Premium?

Having laid out all of the above factors, it is important to point out that each thermometer type offers a premium range of products that can decisively boost their operation potential while significantly smoothing out their disadvantages.

For example, cheap thermocouples may have a bad measurement accuracy, but more premium products can boast accuracy that comes close to the RTD levels. Similarly, there are lab-grade RTDs that are accurate to +-0.01 OC, using very high purity platinum wires and quartz sheaths that cost more to manufacture.

Other RTDs that are intended for use in harsh industrial environments are protected inside a strong casing that renders them equally durable as thermocouples are. Finally, there are specially crafted thermocouples that can measure temperatures of up to 3000 OC. That said if you are leaning towards a choice but are discouraged by the generic features and common characteristics of a thermometer type, check out the premium range. More often than not, it makes a whole lot of difference. These components can be acquired as new or reconditioned units. If you would like more information, please feel free to contact us.

You must be logged in to post a comment.