Do you know how the GE Turbine changed aviation forever? No? Read on!

What Brought GE into Aviation?

You probably know how Wilbur and Orville Wright made their first flights at Kitty Hawk in 1903, especially if you’re located in North Carolina like AX Control, Inc is. Yeah, yeah, we hear you, Ohio ‘first in aviation’ people. Yes, the Wright brothers hailed from Ohio and that’s where they first designed the Wright Flyer. But what sounds like more fun: building or flying? We think flying!

What you may not know is how fast aviation took off (ha!) from there. Within two decades of that 12-second flight from the dunes at Kitty Hawk, trans-Atlantic flights were possible. What’s more, by 1927 Charles Lindbergh managed the flight from New York to Paris without having to refuel.

But as World War I hit its peak, air superiority took on new importance for the entire world. The new technology aided in combat, reconnaissance, troop movements, and defense for both sides.

The National Advisory Committee for Aeronautics (NACA, NASA’s predecessor) reached out to General Electric for help improving the performance of the Liberty aircraft engine. Designed by Packard and Hall-Scott motor company engine designers and built through various contracts by many automobile manufacturers, the Liberty engine had a modular design holding four or six cylinders together by a two-part cast aluminum crankcase with a single overhead camshaft for each cylinder bank. The engines could be one or two banks, which allowed the production of inline fours and sixes as well as V-8 and V-12s.

Unfortunately, the engine’s rated HP dropped significantly from its rated 354 HP as it rose from sea level into high altitudes, slowing the engine and lessening the plane’s maneuverability as it climbed. Something had to be done.

How Sanford Moss Changed Flight Forever

It happens that General Electric hired a young engineer named Sanford Moss to the GE Turbine division the same year Orville and Wilbur got the Wright Flyer off the ground at Kitty Hawk. Moss held a Ph.D. from Cornell University in gas turbine technology and was known at GE for his revolutionary compressor designs. He had already made significant contributions to blast furnace and pneumatic tube system designs by the time NACA approached GE for help.

Moss took on the challenge of redesigning the Liberty engine for GE and NACA. He believed he could reconfigure the compressor design he had used for the furnaces and pneumatic systems to densify air before it reached the Liberty engine’s intake. He called this device, which filled piston cylinders with more air than usual, a supercharger. On its first use test, performed in 1918 at 14,000 feet near Pikes Peak, the engine delivered 99.4% of its rated sea level horsepower. The loss of power was corrected and the experiment was considered successful.

In July of 1919, the first Le Pere biplane outfitted with a newly designed turbocharged Liberty engine took off. By then the war was over. But with the newly designed engine in place, the plane’s speed increased by 52%. Planes using the Moss supercharger went on to set many world altitude records. His design set the groundwork for more improvements that would soon follow.

GE Ushers in the Jet Age

Moss continued working on his supercharger. His supercharged engines–improved from their 1920 design but still using the same primary design–found their way into World War II planes like the Boeing B-17 Bomber, the P-38 fighter, the P-47 Thunderbolt, and the Consolidated B-24 Bomber.

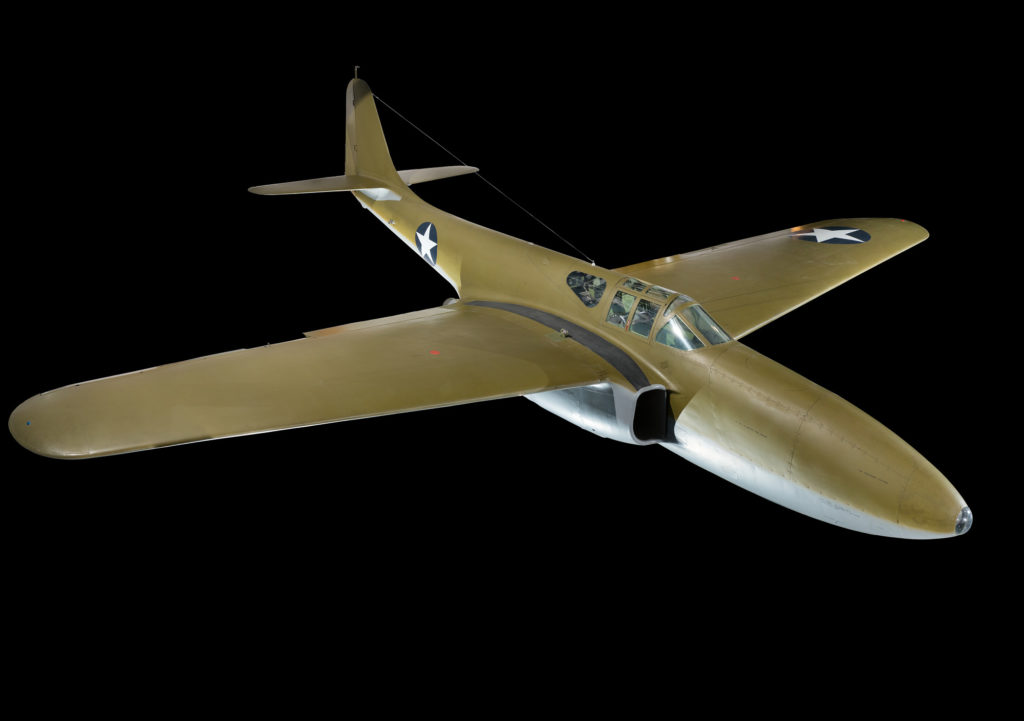

Meanwhile, another group at GE called the Hush-Hush boys expanded on Moss’s theories. These engineers worked on a top-secret prototype called the I-A, which was later renamed. In 1942 the XP-59A, America’s first jet, took its maiden flight from Lake Muroc, California with GE turbocharged engines on-board.

GE Turbine: Other Applications

When Sanford Moss built that innovative design over a hundred years ago, he changed more than aviation. Derivatives of his design live on within other parts of GE, where gas turbine technologies play a big part in the company’s business model. Turbines and associated products are used in nuclear reactors, heat recovery steam generators, solar panel farms, oil production equipment, and measurement and control systems. Additionally, a GE turbine system currently holds the world record for powering the most efficient combined-cycle plant.

GE Aviation Today

GE Aviation is still one of the largest subsidiaries of General Electric and one of the biggest players in the aviation sector. Headquartered in Ohio, they have facilities in North Carolina, Kentucky, Michigan, Vermont, New Hampshire, and Quebec.

Today’s GE Aviation still makes jet engines. In fact, they make all kinds, including turbojets, turbofans, and turboprops. They also make turboshaft engines that are most often used in helicopters. More recently they’ve also developed industrial and marine aeroderivative engines used to propel warships like the Royal Danish Navy’s SF300 class.

Do you need help with replacement parts for any of your industrial GE control systems? AX Control maintains on-hand stock for many hard-to-find GE products, including Speedtronic systems and GE Multilin Motor managers. Talk to our team today!

You must be logged in to post a comment.