Gas turbine protection systems are complex animals. They have many subsystems that must run at each stop and startup. Emergency systems back these up, kicking in when necessary.

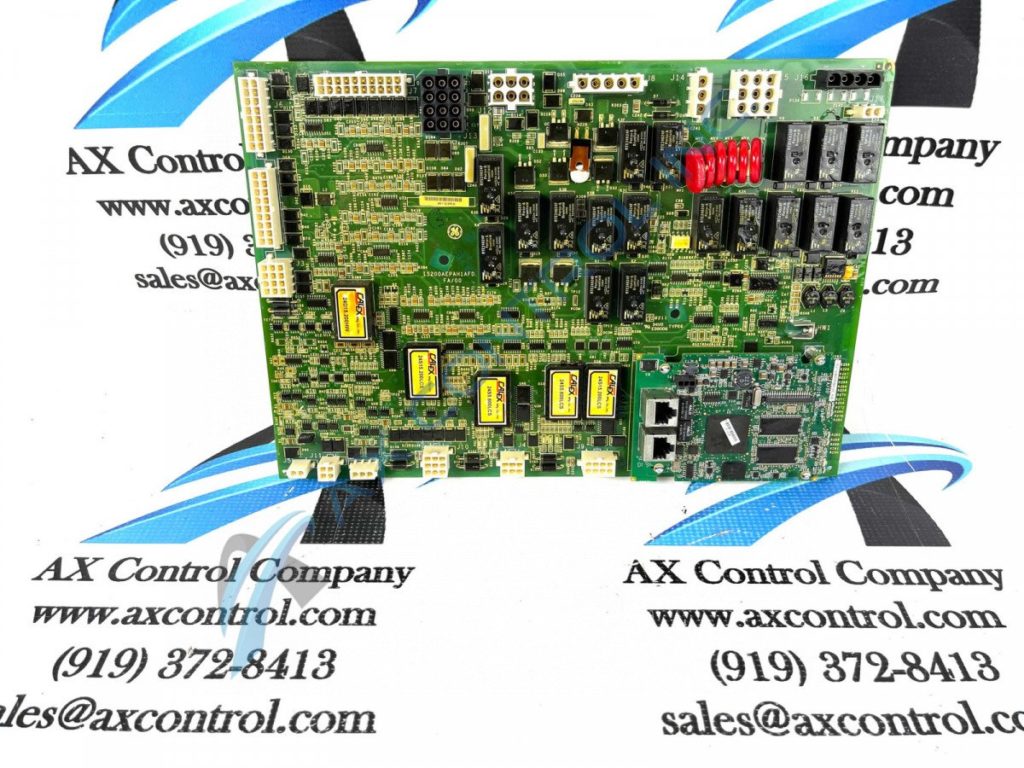

The most difficult thing about setting up control systems for gas turbine systems is their variability. Successful protection systems have to adjust from project to project, but that’s not easy. A flexible-by-design approach helps. The modular nature of the Speedtronic Mark VI helps meet this need.

Commonly, gas turbine failures are caused by sensor failure or wiring failure of the sensor protection system. These detect alarms. When protection is completely disabled, the turbine can trigger. This allows the turbine to respond to over-temperature and speeding settings.

Many types of gas turbines use Speedtronic Mark VI control systems. But for the rest of this blog post, we’re going to consider a single-cycle double-shaft mechanical drive system with a gas turbine using an axial compressor.

Regulation of such a turbine occurs through start-control functions. Sensors monitor speed, exhaust temperature, compressor discharge pressure, and other variables; this dictates unit operating conditions. When a modification is needed because of environmental or load changes regulation occurs through supervision control modules within the gas turbine system.

Control: From Zero to Operating Speed

Control begins when the turbine passes from “speed zero” to its safe operating speed. This happens through proper fuel supply to initiate flame speed while minimizing the fatigue cycle down. Control signals to the fuel-regulating system must be appropriately sequenced.

Device sequence should be checked as the startup begins. Successful startup hinges on turbine equipment working properly. Yet so many of the control logic circuits are connected to valid protection circuits and permissive conditions as well as operating control devices.

The turbine control system changes the flow of fuel gas to the combustion chambers in response to the FSR, or fuel stroke reference signal. Operation begins with the servo-drive. Here, a comparison of the setpoint and feedback signal happens. This converts to a valve position.

As this is happening, protective circuits and the master Speedtronic system are both working. Additionally, entirely mechanical systems are also in play. Because of this, there are two ways to stop fuel flow: the inlet of the liquid fuel valve, or the FSV, and the fuel control valve (RST). These independently controlled systems each offer control against damage by over-speed. Rotor speed is typically controlled by speed control.

Real-life Fail-Safes

In real-life applications, the Mark VI system includes an over-temperature system to protect the gas turbine from a spark. It operates if the temperature regulating system fails.

Likewise, the exhaust temperature control system will control fuel flow when ignition temp limits are reached. This occurs under normal operating conditions. But if the turbine is in failure mode, the fuel flow rate can exceed control limits. If this happens, the area of the turbine flow rate will rise to maximum.

The Mark VI system includes twelve thermocouples installed within the turbine exhaust chamber. Averaged data from these thermocouples determine latching and alarming.

Looking for a Mark VI parts supplier? Then we can help! Talk to our team today.

You must be logged in to post a comment.