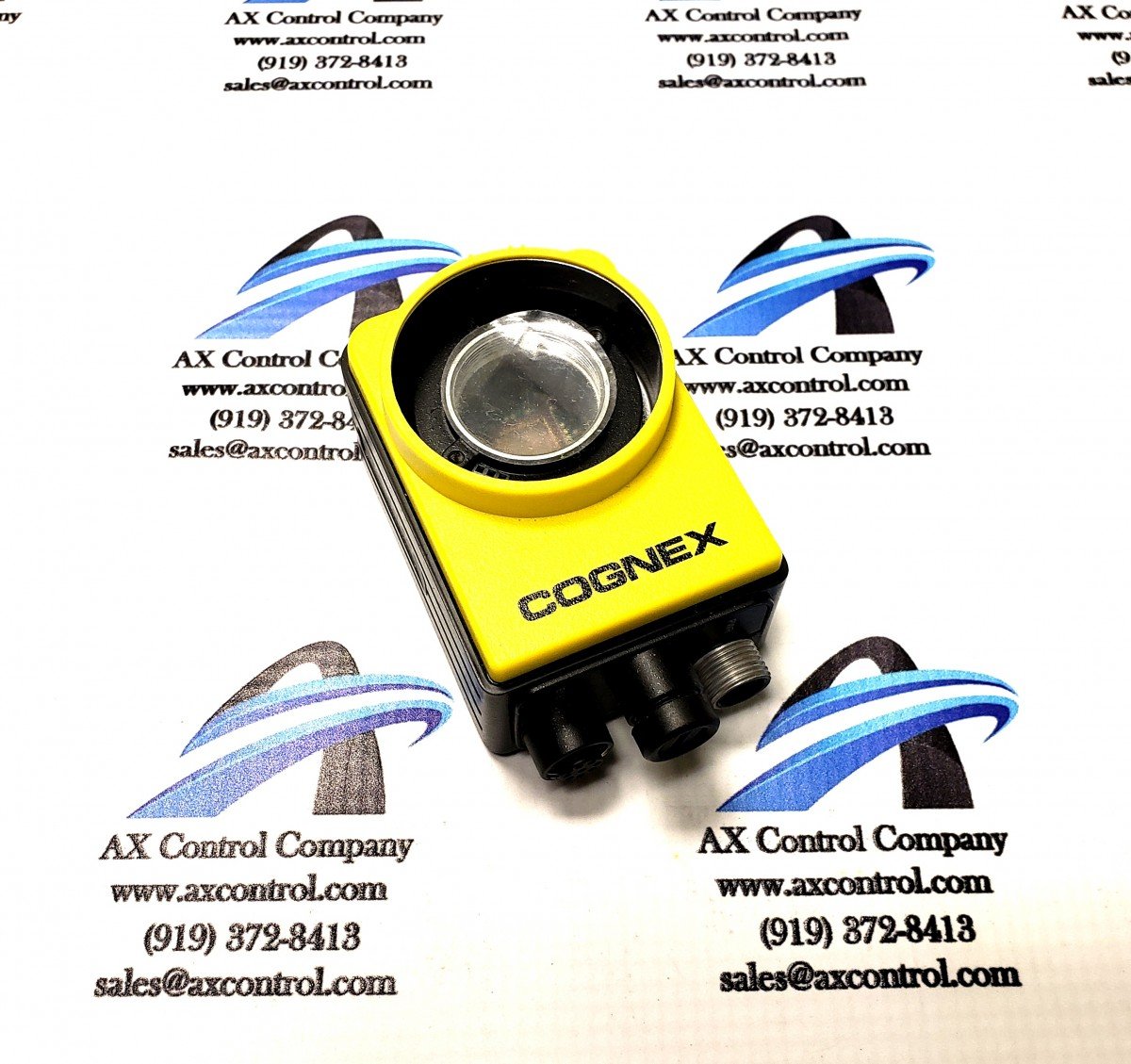

What Is Cognex InSight?

Cognex InSight is a family of vision systems typically used on the factory floor to identify, inspect, and guide parts. Depending on the model, In-Sight cameras offer high-resolution and high-speed built into a rugged body capable of holding up to demanding industrial applications with pinpoint accuracy.

How to Find the IP Address of a Cognex InSight Vision System

New Cognex vision systems have DHCP (Dynamic Host Configuration Protocol) enabled. This means your camera will listen for a DHCP server to assign it an address. However, if this does not happen automatically the Cognex In-Sight camera will default to a Link-Local IP address in the 169.254.xxx.xxx range.

You must be logged in to post a comment.