Electrical equipment has the same need for air and cooling as human beings. Without a proper air supply, machines will flounder and fail. You have to protect equipment from heat damage, or they’ll die. But these expensive casualties don’t have to occur.

Pull out the manual for any equipment in your plant, and you’ll probably see a bolded notation stating its proper operating temperature range. Keeping equipment operating within this range makes sure those machines remain an efficient and reliable part of your operation, and avoids the cost associated with failures like unexpected shutdown, deteriorated performance, and shortened equipment life, not to mention the need to replace damaged equipment.

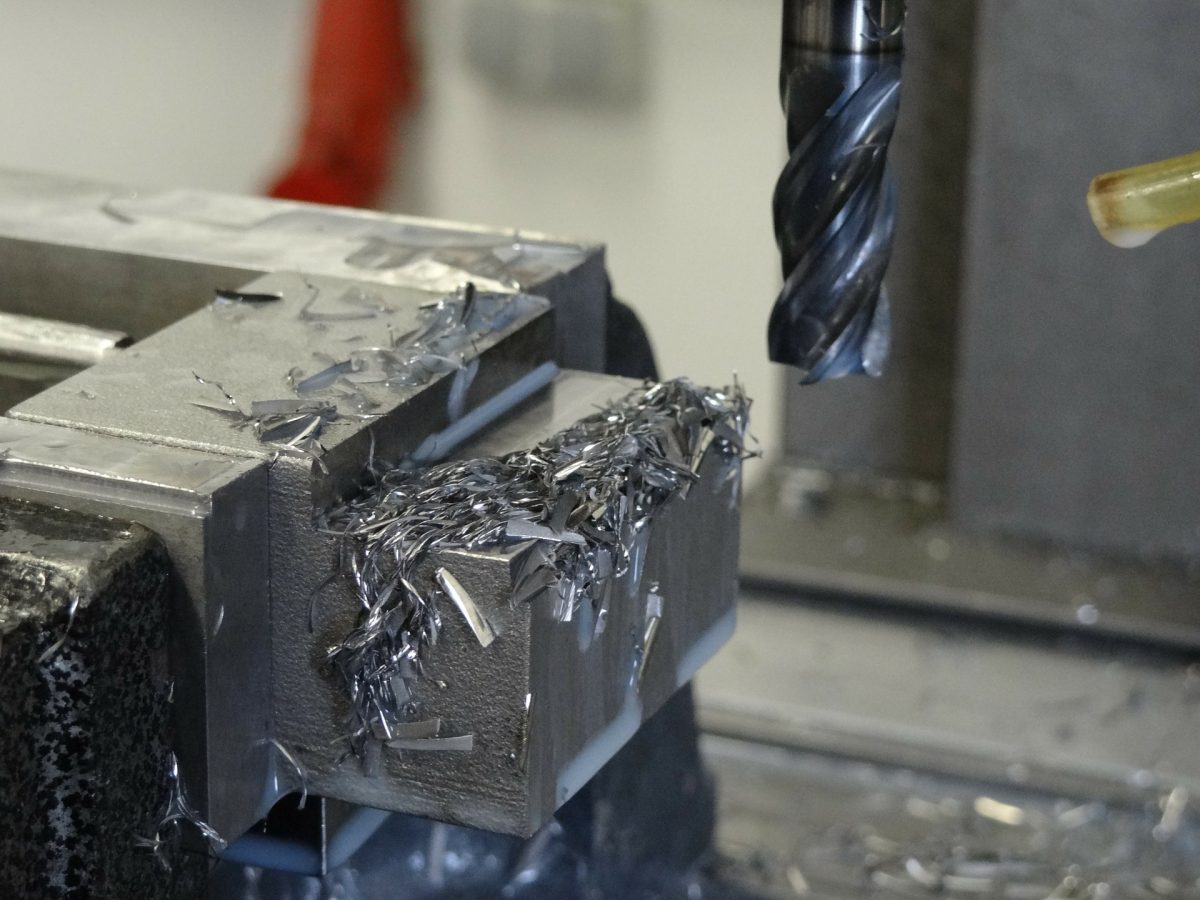

Sustaining proper operating temperature is especially important in CNC machines where machine precision can be affected by thermal errors. Machines running outside their proper operating range have significantly more errors than those running within range.

Is basic maintenance enough?

Basic maintenance is a good first step for protecting equipment. The primary source for damaging heat comes from within the equipment’s own enclosure. As temperatures increase, lifespan decreases: a 10C change can cut a machine’s lifespan in half. While new, clean equipment can easily maintain proper operating temperature, internal temperatures will increase as particulate matter like dust, debris, pollutants, or dispersed oil sit on the surface like a thermal blanket and create a topical barrier.

Continue reading “Is Maintenance Enough to Protect Equipment from Heat Damage?”

You must be logged in to post a comment.